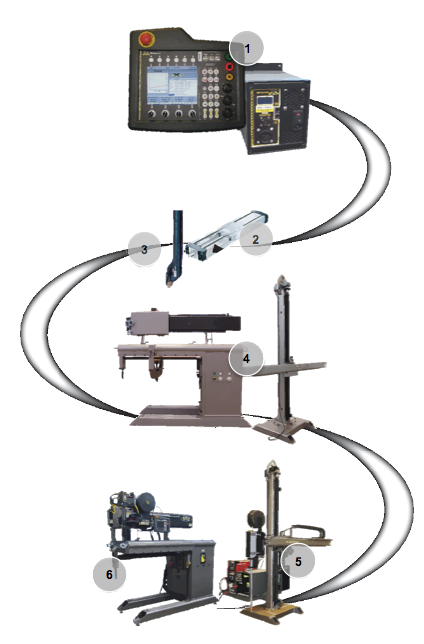

Standard Features on 设备控制系统改造

1

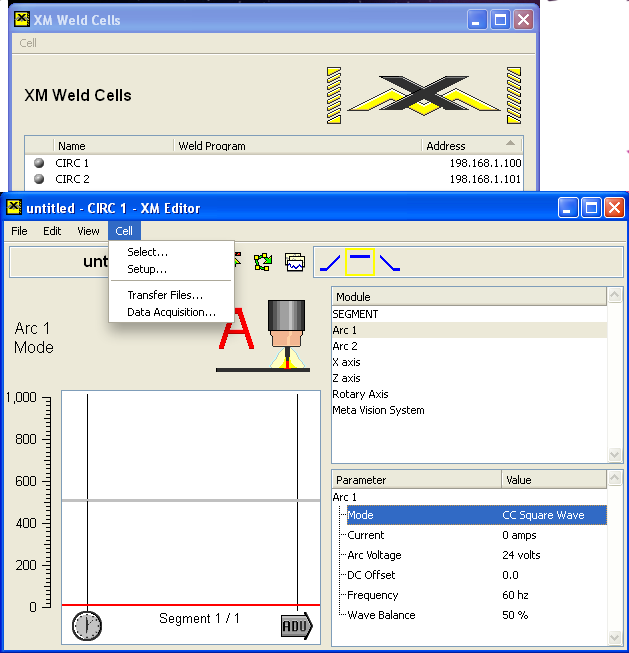

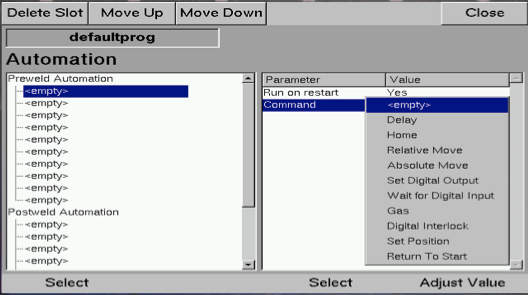

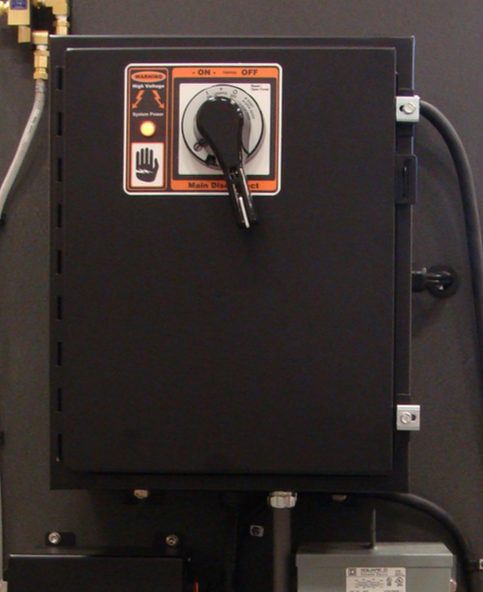

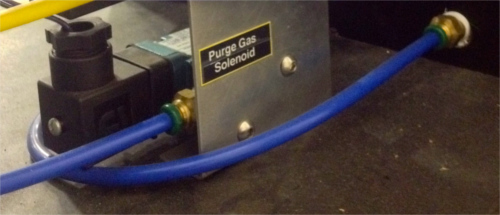

AMET Advanced Controls. The architecture used in AMET’s controls allow us to accommodate a wide range of power supplies, fixturing, safety, and automation equipment. The controls are designed and built in house to seamlessly integrate with existing equipment.

2

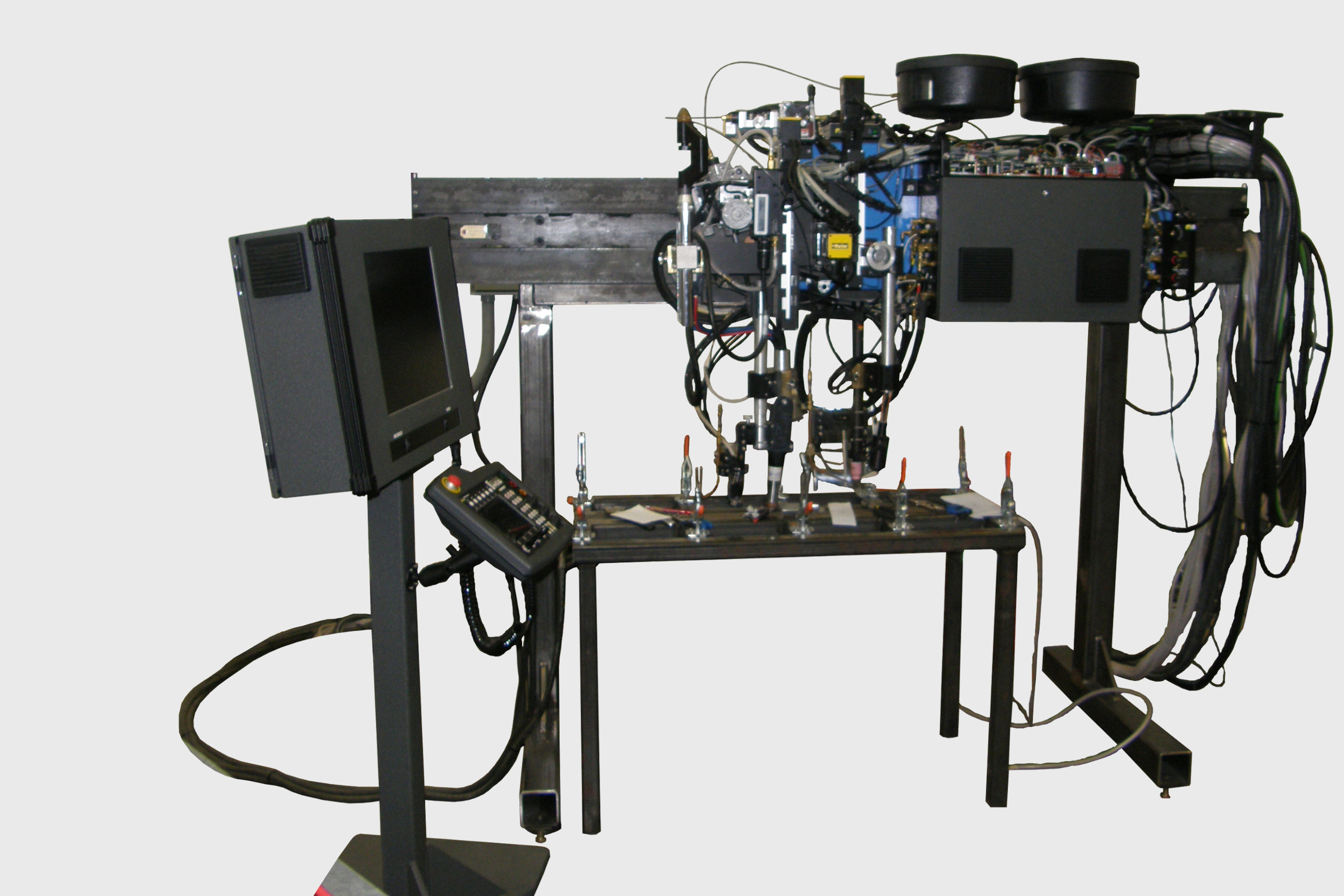

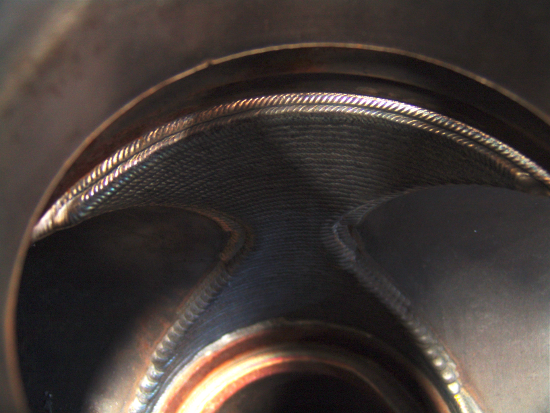

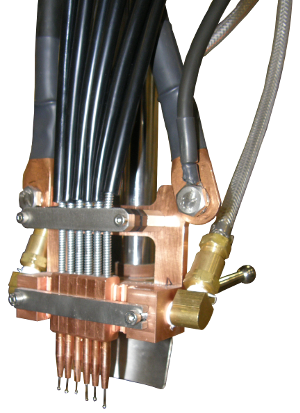

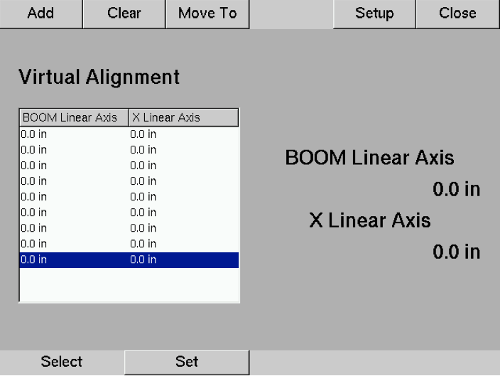

Precision and Manual Motion Axes. AMET produces and integrates motion axes and the necessary bracketry for vertical and horizontal weld head movement. The precision axes consist of servo motor driven components with encoder feedback for programmable motion and position. Manual axes are hand crank driven slides with manual brakes to prevent movement during welding operations.

3

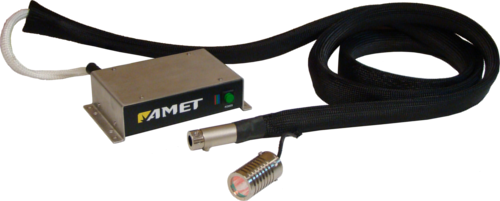

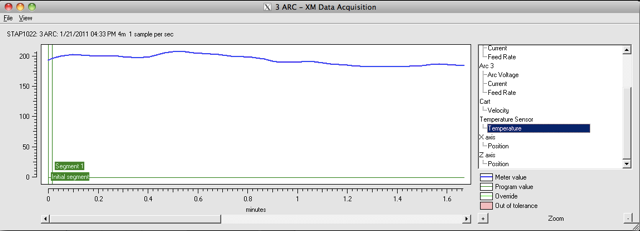

Testing. AMET control components are produced in house, which allows us control over the quality and the ability to test each component as it is produced. This includes individual components such as control boards and complete assemblies like control modules and the XM Controller. Each component and assembly is rigorously tested, as is the whole system to ensure proper functionality, compatibility and longevity.

4

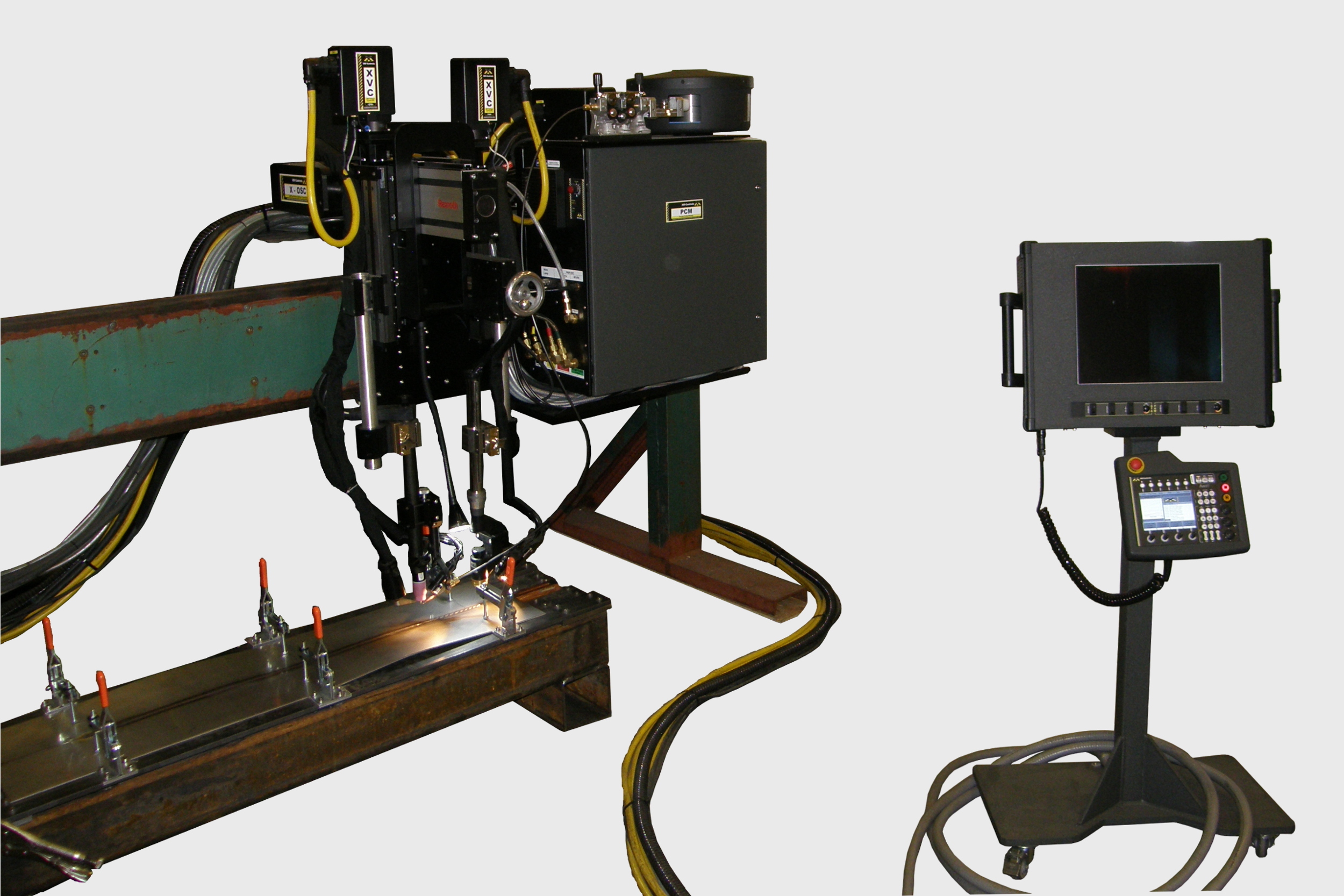

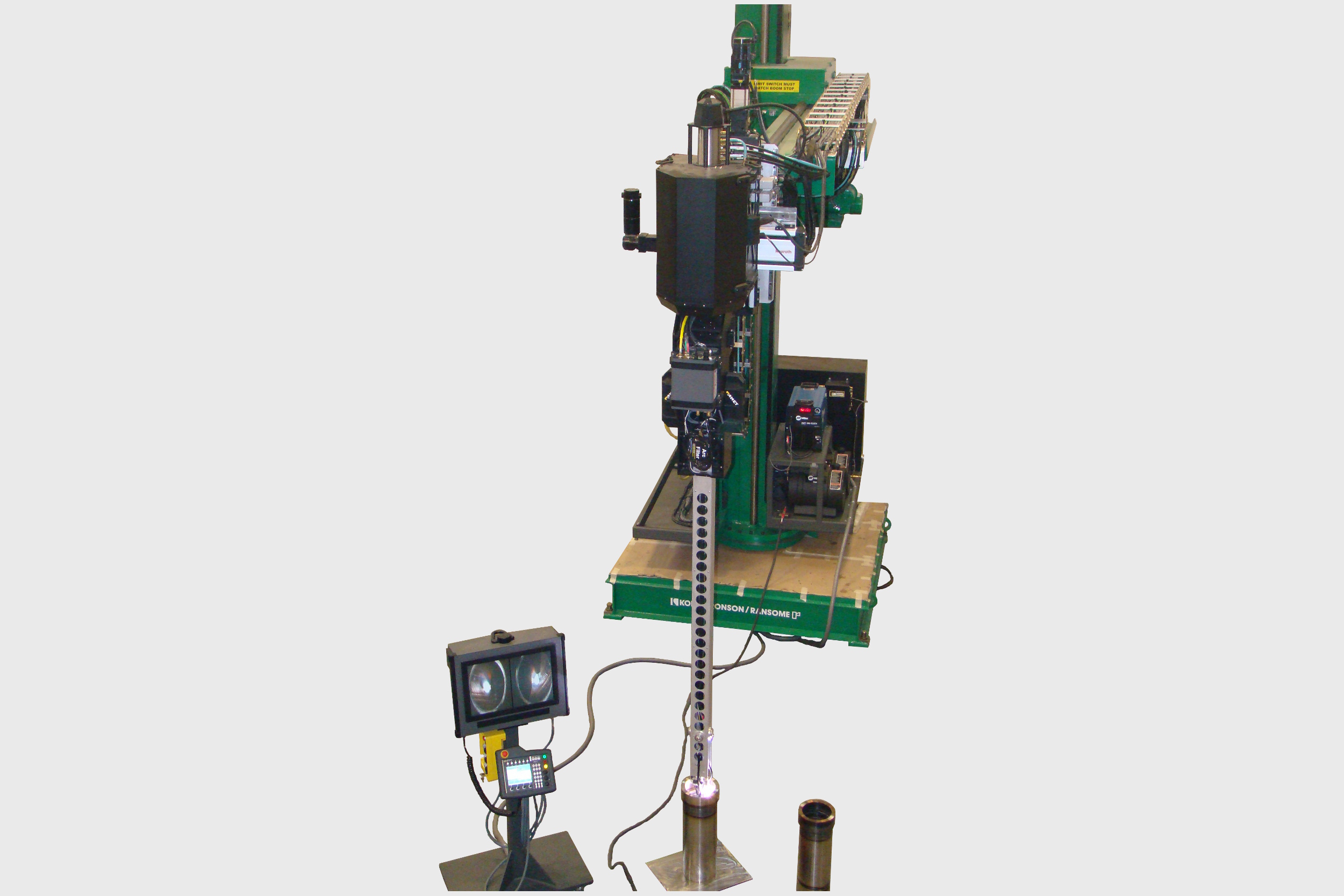

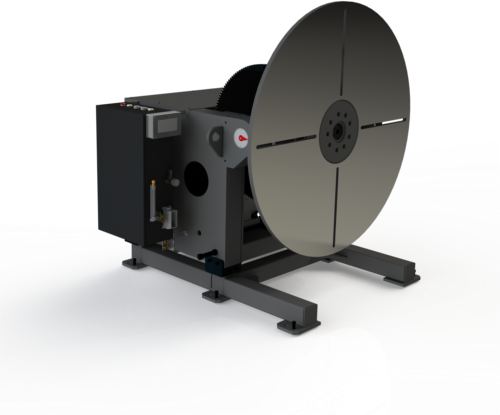

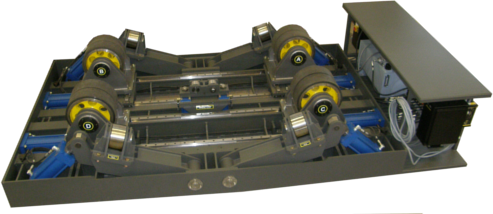

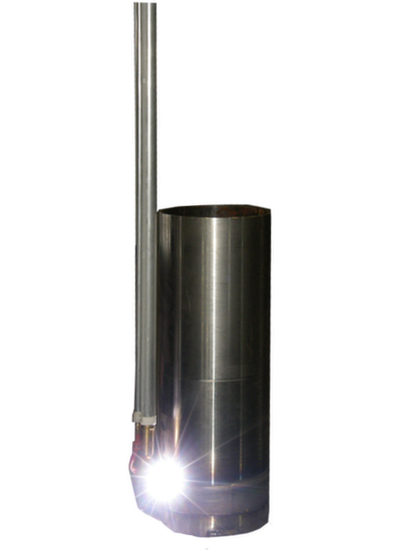

Fixturing. AMET performs retrofits on manipulator, seam welder, lathe, positioner, and cladding fixturing made by virtually any manufacturer. The fixturing can be new or used as long as it is functioning adequately at the beginning of the retrofit process.

5

Integration. The controls and motion components are integrated with the fixturing for performing hard automation welds. The advantage to an AMET retrofit is that we design the software and hardware of our controls to seamlessly integrate with each fixture. This holistic approach ensures compatibility with virtually any weld fixture.

6

Complete System. AMET provides complete systems with a warranty on all AMET produced components. Upon completion of testing and integration at the AMET facility in Idaho, we setup and install the retrofit system onsite at the client’s facility.