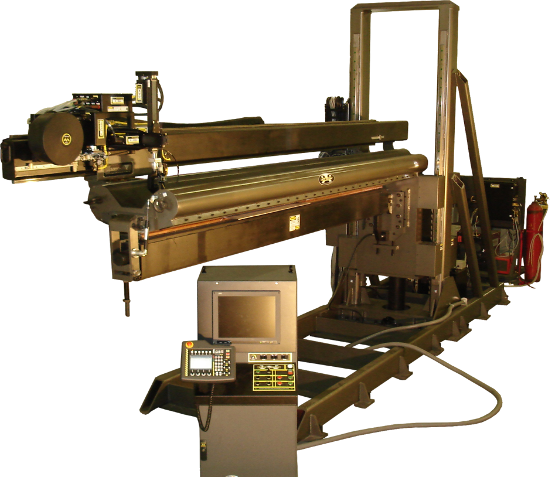

Standard Features on Linear Seam Welder (LSW)

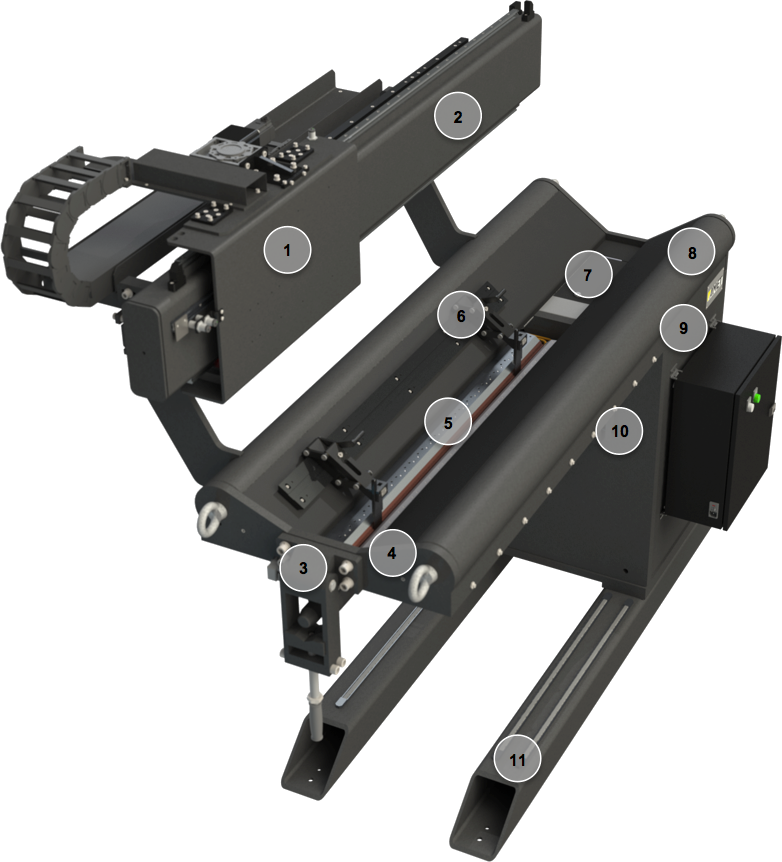

1

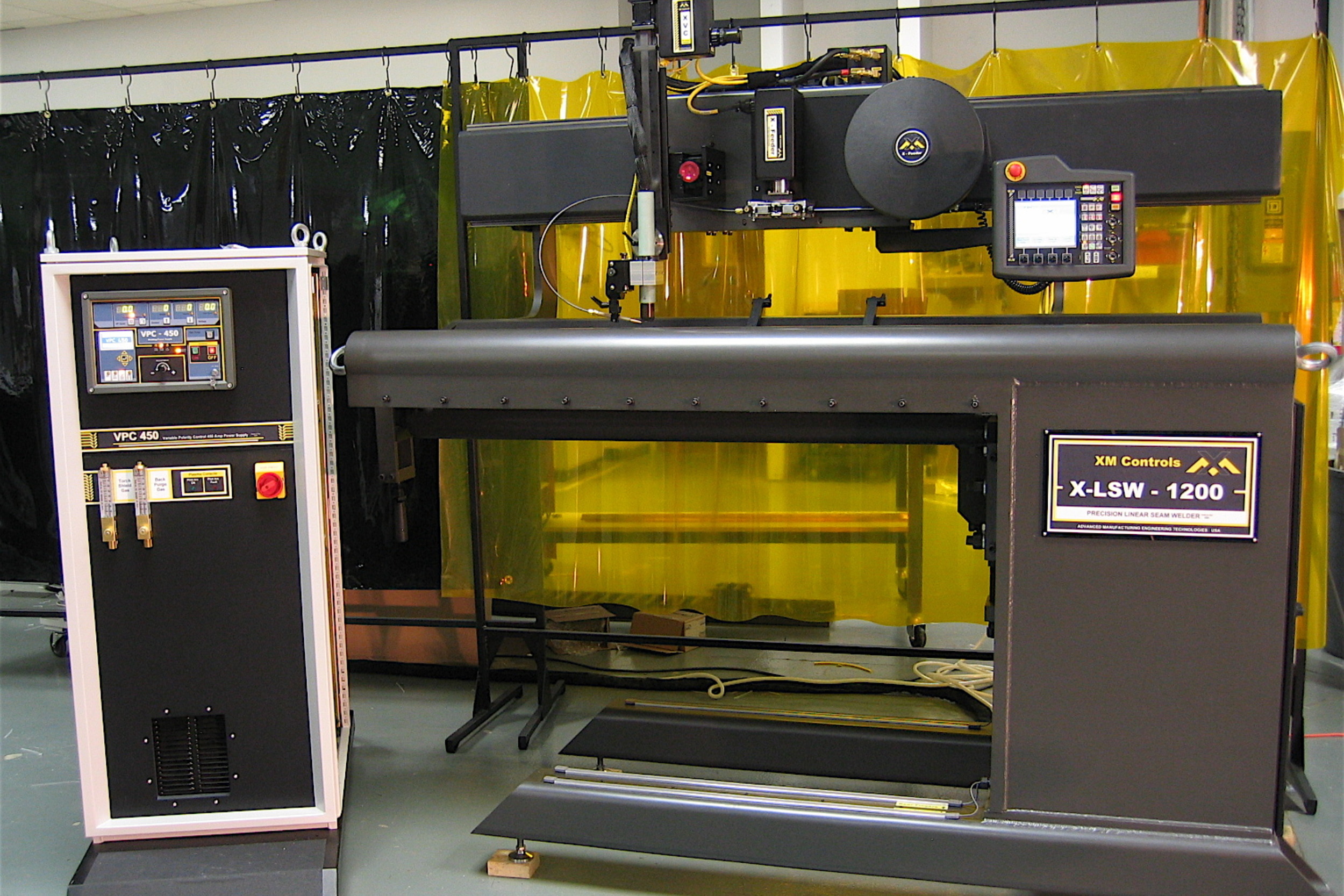

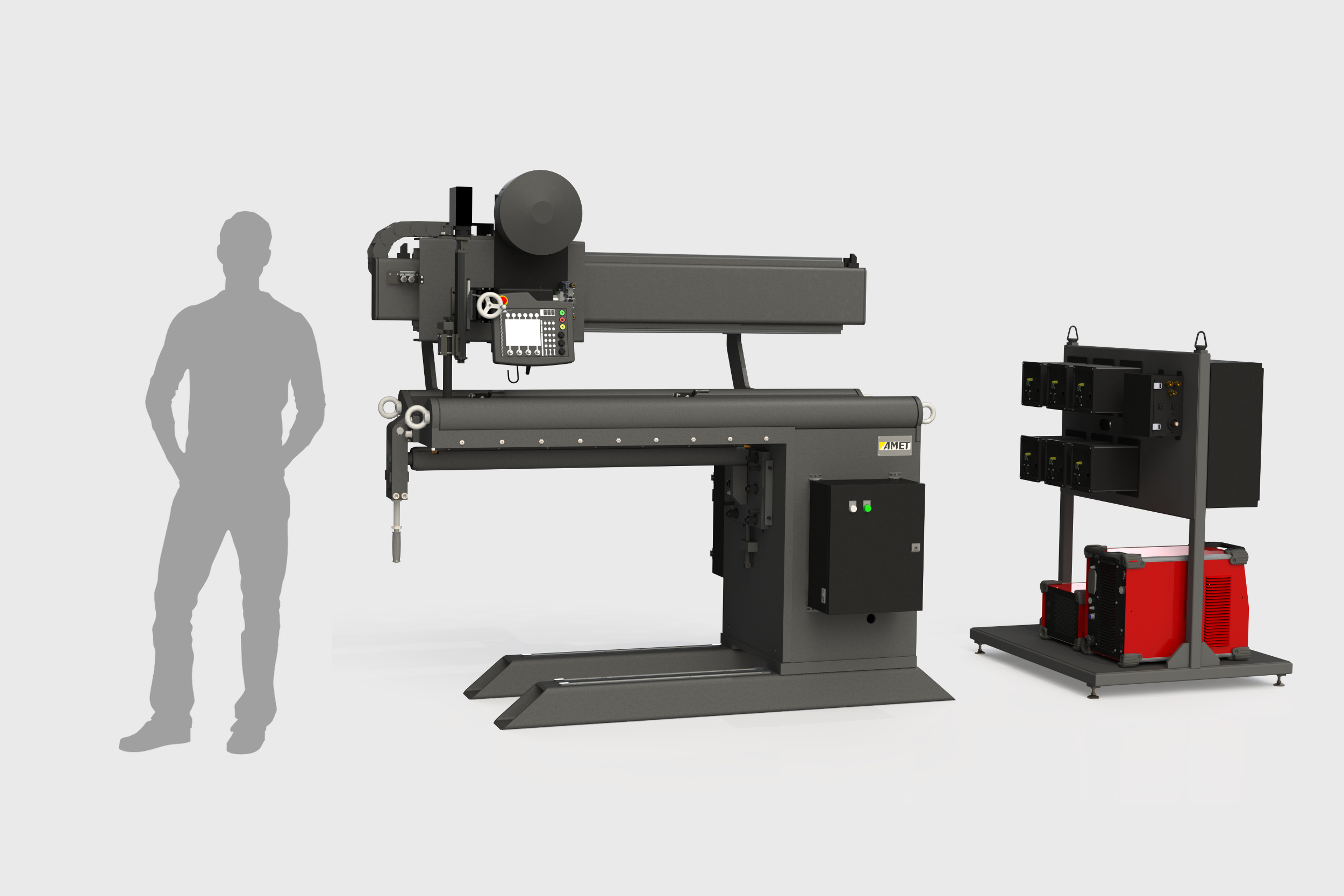

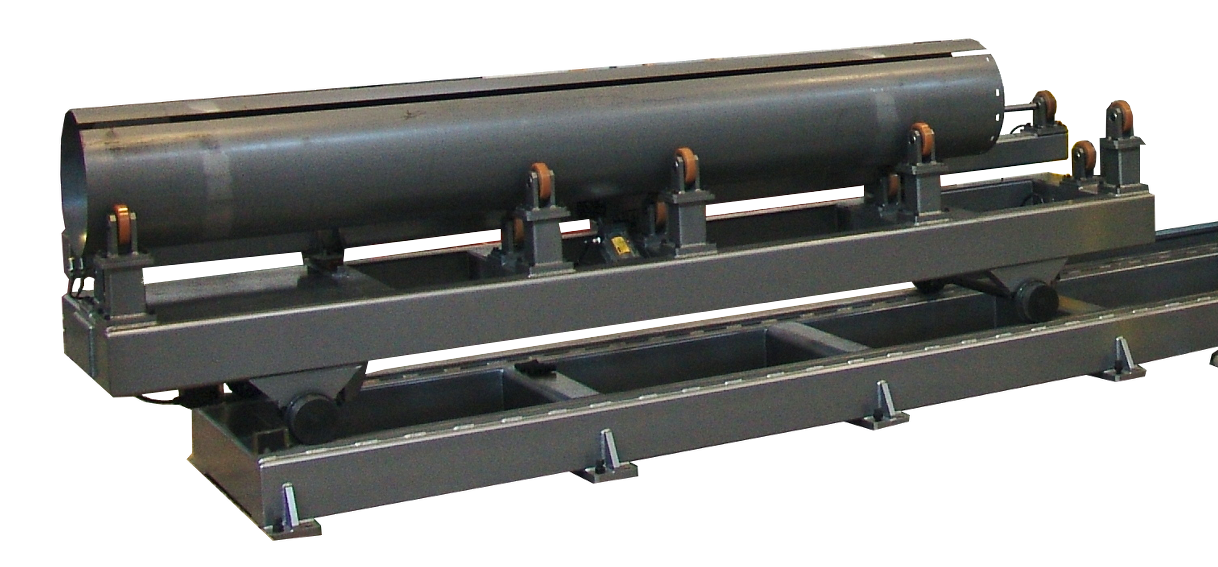

A travel carriage rides on four (4) precision linear rail bearing blocks and is driven by the pinion gear mounted to the carriage gearbox and servo motor. Home and travel limit switches are included, further enabling precise and repeatable welds. A cable tray and cable carrier is also included and provides a neat cabling package, as well as extending the life of the cabling and hoses running to the seam welder carriage and weld head.

2

The seam welder track is stress relieved prior to machining, which maintains tight tolerances and dimensional stability over the lifetime of the equipment. The track is outfitted with precision ground linear rails and a gear rack which provides smooth, repeatable motion resulting in superb welds.

3

A safety interlock switch is provided at the mandrel latch. The integration of this switch prevents the seam welder from clamping when the mandrel latch is in an open condition. It also prevents the seam welder from unclamping the part while the weld is in progress.

4

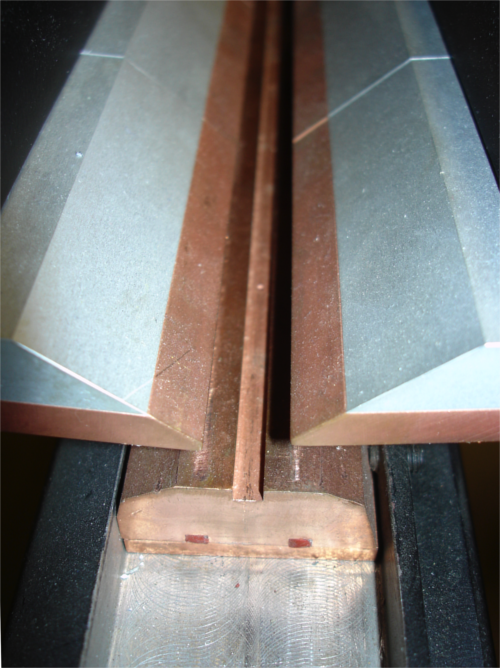

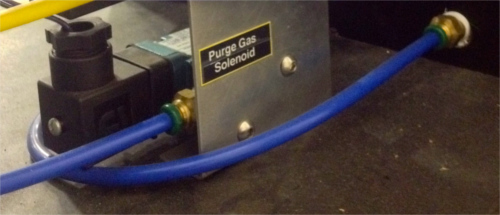

Double wall pneumatic hose provides uniform clamping force to each of the clamping fingers along the full length of the weld. A pressure regulator is provided to allow adjustment of the clamping force. The aluminum clamping fingers are fitted with copper fingertips that are reversible to double their service life. The copper fingertips provide excellent heat conduction and aid in chilling the weld zone during the weld. The seam welder’s fingertips may be replaced individually as needed.

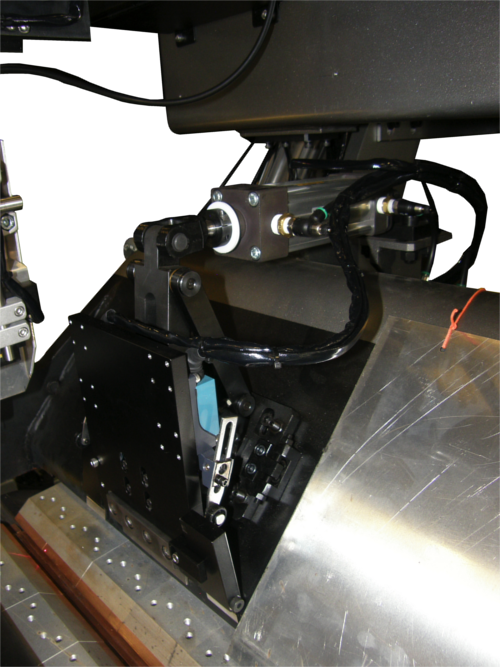

5

The finger-to-finger distance between the front and back clamping fingers may be adjusted, thus allowing the fixture to be fine-tuned to the welding process and materials being welded. This adjustment comes in two ranges. The first offers adjustment from 3mm to 30mm (0.1 to 1.2 in). The second offers adjustment from 10mm to 44mm (0.4 to 1.7 in) and is more often used for SAW and GMAW welding processes.

6

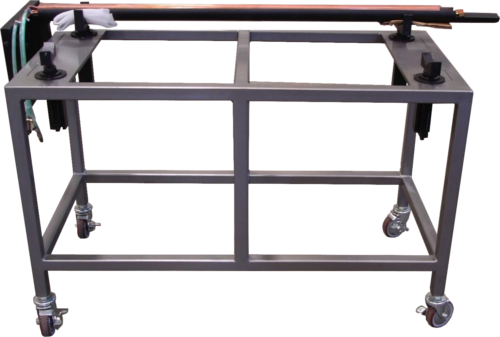

Two (2) manually retractable part alignment devices facilitate positioning of the weld joint along the centerline of the seam welder prior to clamping and welding. These alignment devices may be easily repositioned along the length of the seam welder bed, allowing them to be placed appropriately for parts of varying lengths.

7

A built-in storage area is included above the seam welder’s mainstay. Tools or consumables may be stored in this area, keeping them within easy reach and reducing down time.

8

The seam welder mainstay incorporates an accessible area that may be used for mounting the welding and motion controls, depending on the complexity of the welding system. Having this area available for housing control components helps reduce the number of items that may otherwise have been mounted to the weld head carriage.

9

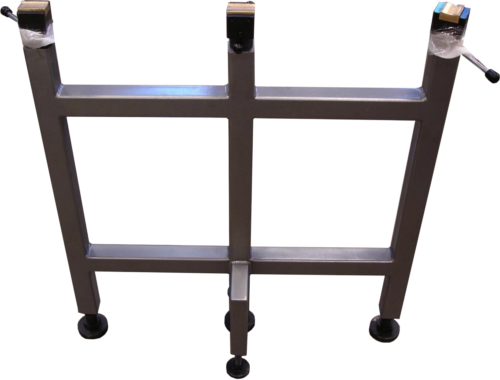

AMET Seam Welders utilize heavy-duty, thick wall structural steel construction to minimize part distortion during clamping. The added mass also provides superior heat absorption and dissipation during the welding process, while at the same time increasing the rigidity and extending the equipment’s service life.

10

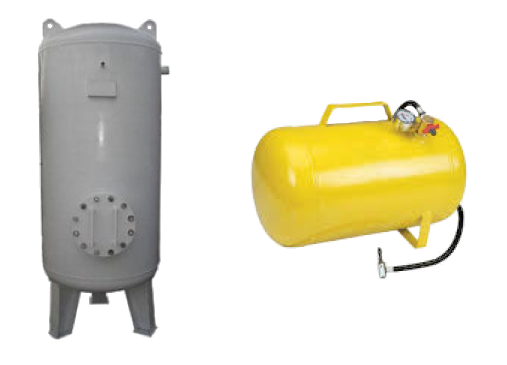

The adjustable height seamer mandrel accommodates materials of various thicknesses and is plumbed to accept water cooling to help draw heat out of the weld joint. The seamer mandrel is supplied with one (1) standard copper backup insert. The groove in the insert is machined to match the material type and thickness that is being welded, as specified by the client.

11

Foot-activated tape switches are used to operate the pneumatic clamping and unclamping of the seam welder fingers. A single tape switch is mounted to the back leg of the seam welder and controls the back clamping fingers, while dual tape switches are mounted to the front leg and control the front and back clamping fingers respectively.