Defense

Puget Sound Naval Base. AMET has provided multiple systems to the naval base for various applications.

Los Alamos National Lab. AMET has provided several systems to Los Alamos for defense and other applications.

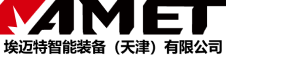

Manipulator system built for Puget Sound Naval Base.

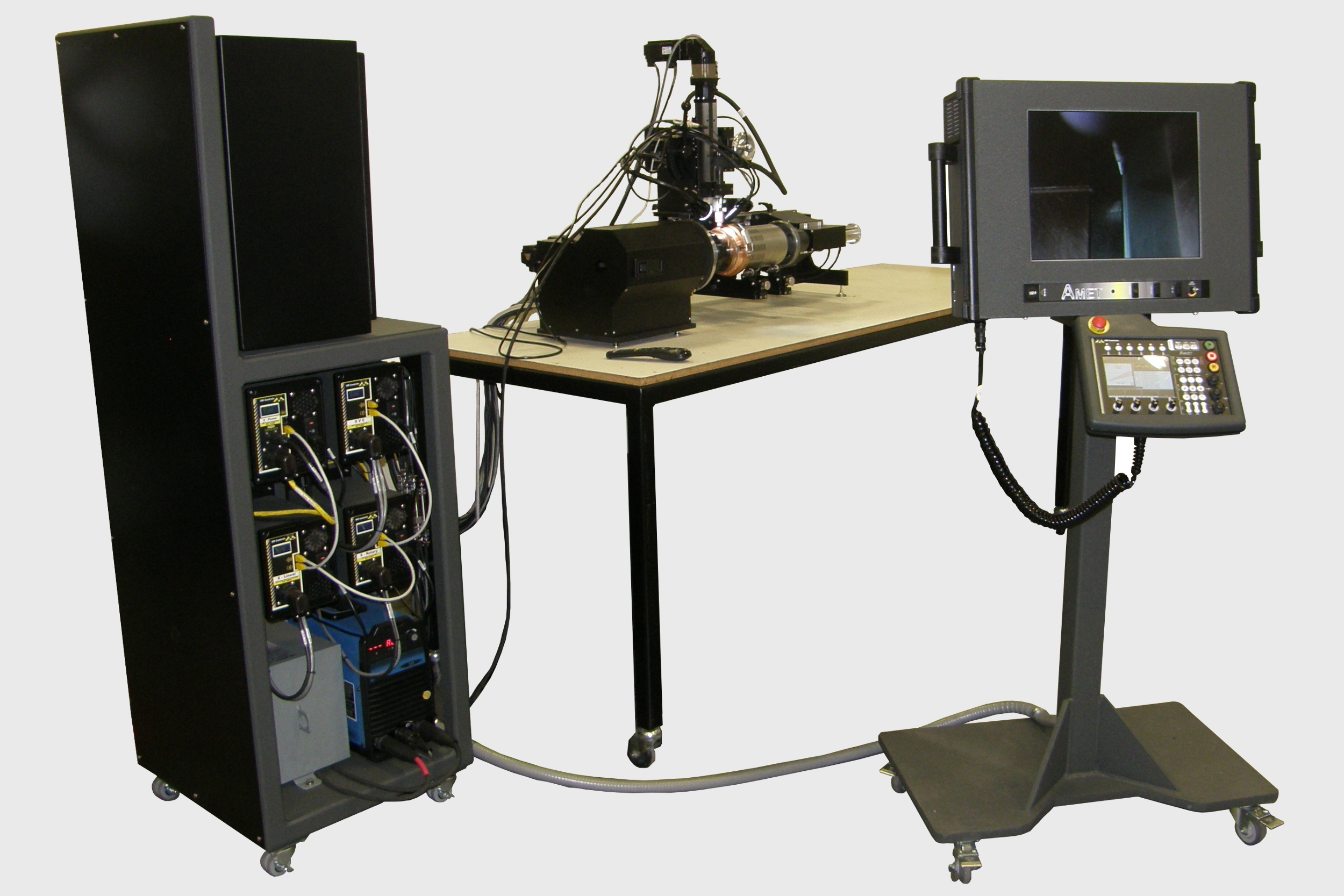

Small vertical lathe built for Los Alamos.

Precision Benchtop Lathe built for Los Alamos.

General

AMET produces several automated systems for the Defense Industry. This industry has a wide range of applications, which often require high-precision motion to ensure the integrity of each part is maintained. Our systems include solutions for naval shipyards, national laboratories, and defense contractors.

The systems we provide for this industry range from standard setups such as manipulators and lathe welders to completely custom solutions. We specialize in customizing our controls and weld fixtures to meet the stringent requirements that are common in the defense industry.

Related Products

Case Studies

The Need

The Defense Industry is widely diverse with stringent quality control measures in place to help ensure each part is welded correctly. Precision, welding fixture robustness, and the ability to control velocity and positioning are essential for most welding applications in the defense industry.

Solution

AMET builds several welding solutions for the Defense Industry. Each of our systems is equipped with servo motors with encoder feedback to provide precision velocity and positioning control.

We offer a full-line of welding fixtures including manipulators, seam welders, lathes, positioners, and custom fixtures. Each of our fixtures is built with an emphasis on rigidity and precision. Machined bearing rails and thick wall tubing is used in the construction of these fixtures to increase precision and rigidity.

We also offer Data Acquisition and Tolerance Checking software for built-in quality control. The software monitors each module of the system and can automatically extinguish the arc and proceed to the slope out segment of the weld program if any of the modules exceeds the programmed values.

Result

Our systems are proven. We have over 25 years of experience and several systems that are currently producing high-quality parts for the Defense Industry.

The combination of our controls, precision motion components, built-in quality control capability, and rigid welding fixtures provides a complete welding solution that will produce consistent and uniform parts for years to come. We produce all of our controls and software in-house, which allows us to provide years of service after the sale. Our ability to diagnose, repair, and service each system prevents obsolescence and provides a good return on investment.

One of our greatest strengths is our knowledgeable customer service department that will support each system expertly and courteously.