Standard Features on 定制焊接系统

1

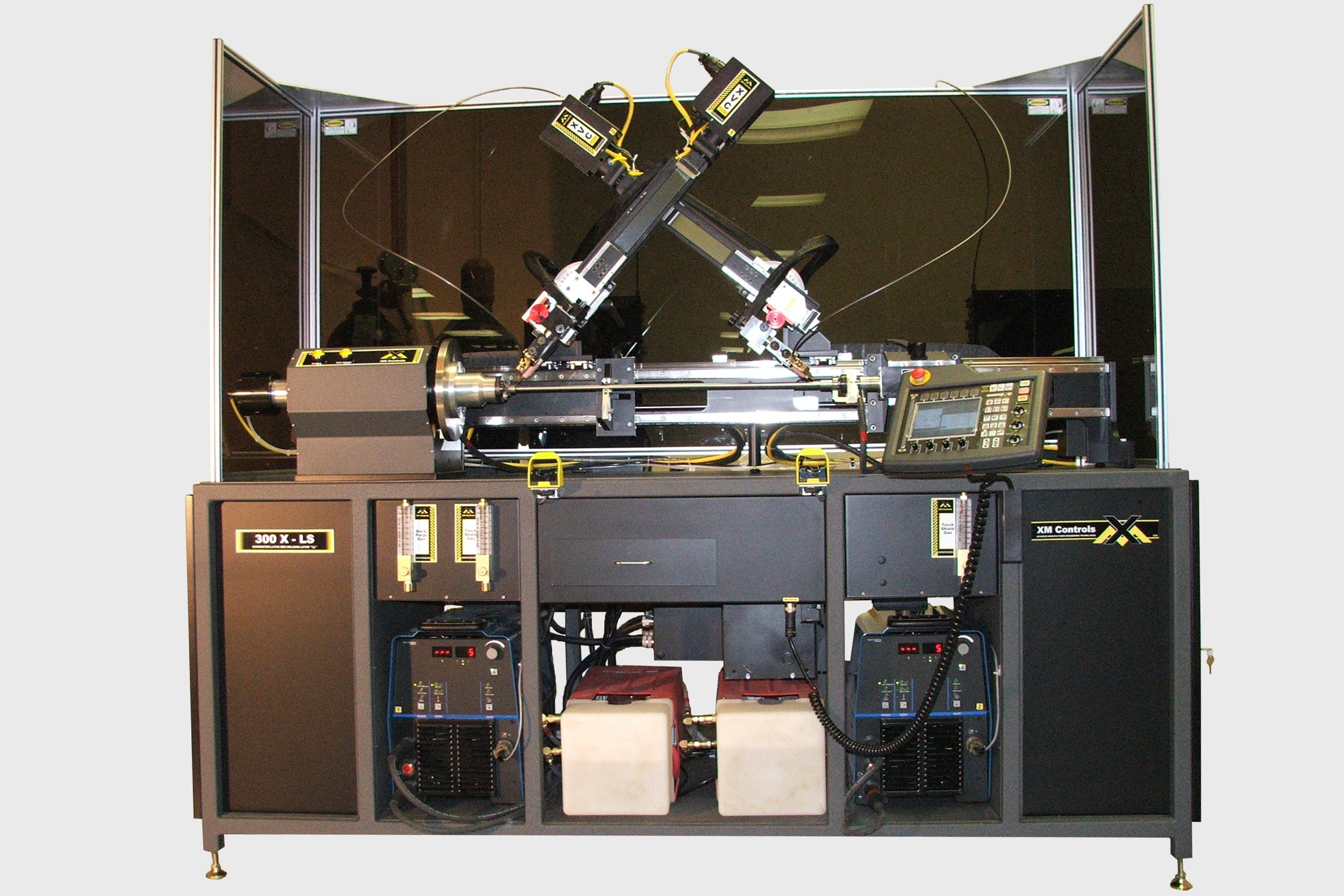

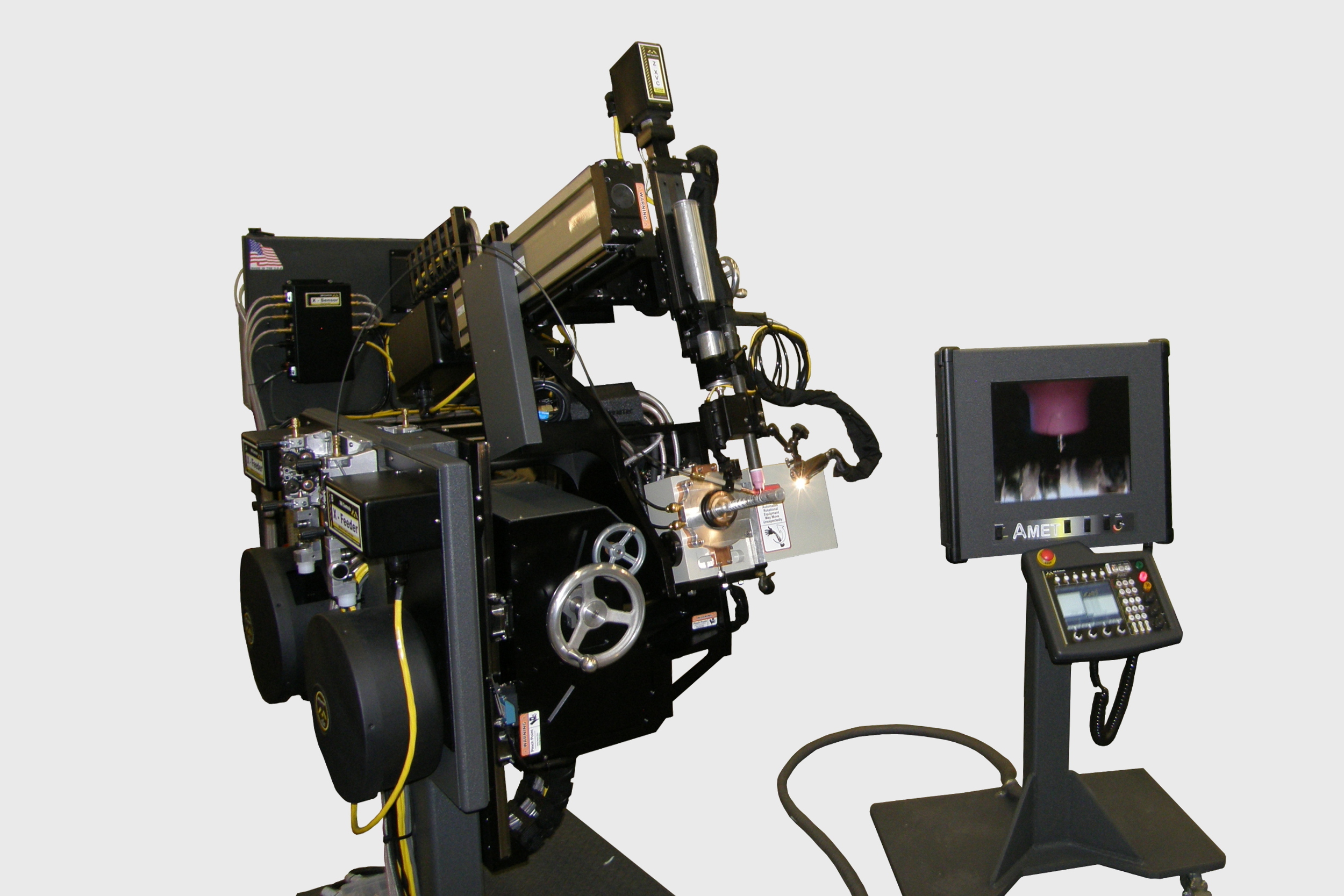

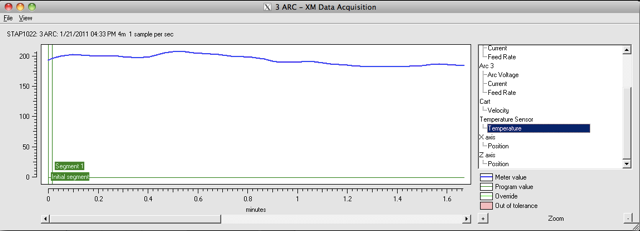

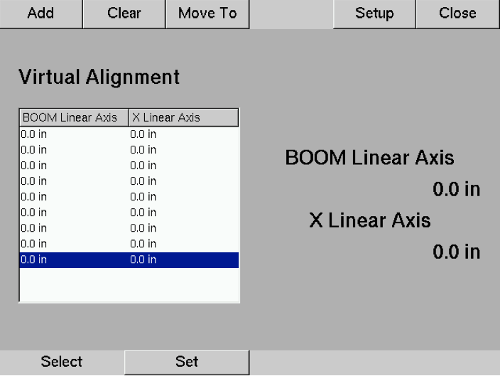

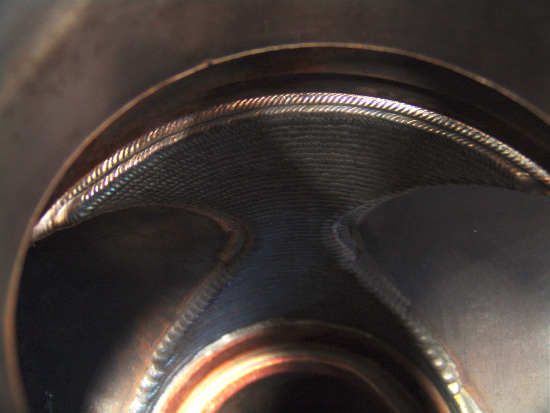

A huge benefit to our custom systems is the combination of hardware and software that is designed in house to work together.

2

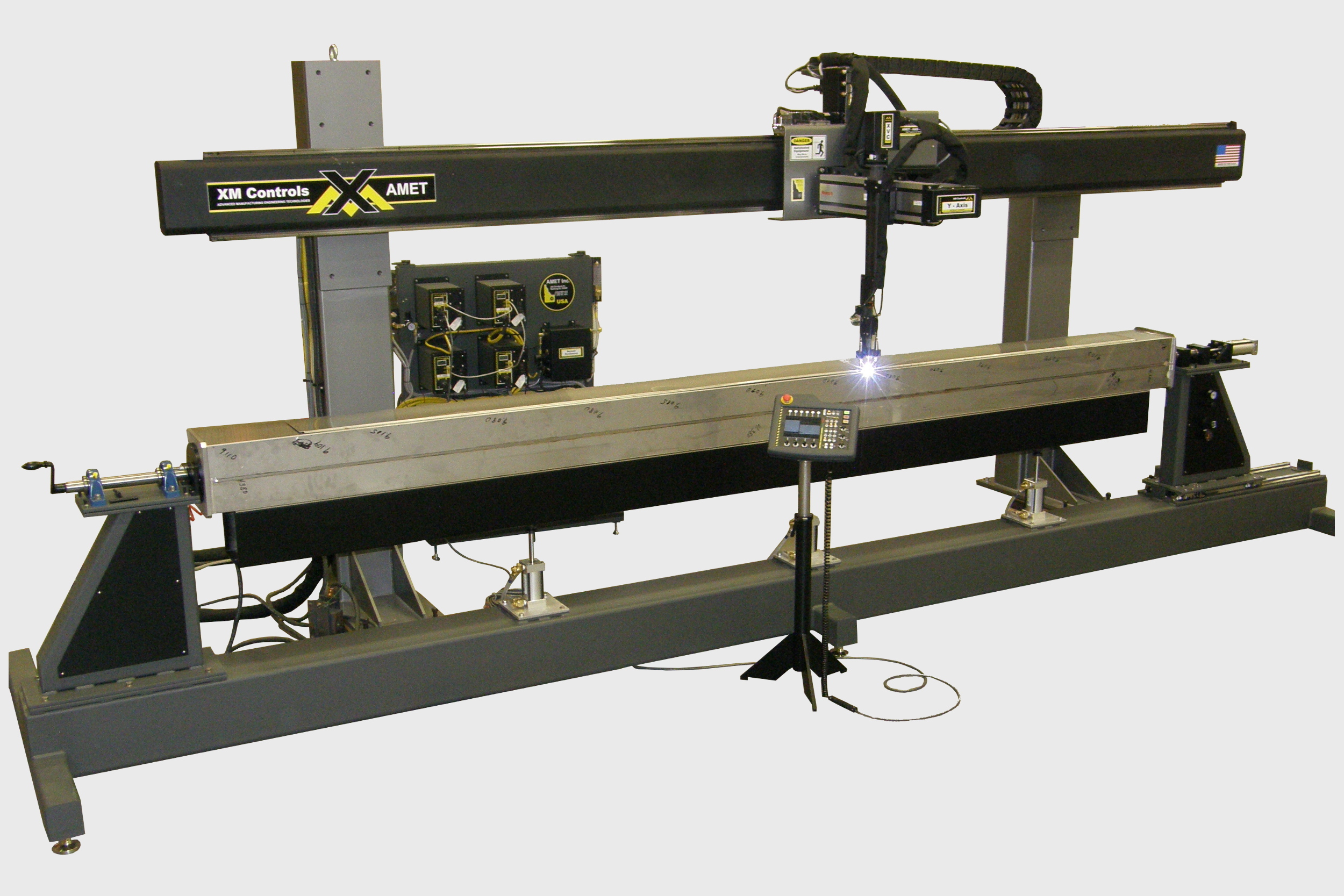

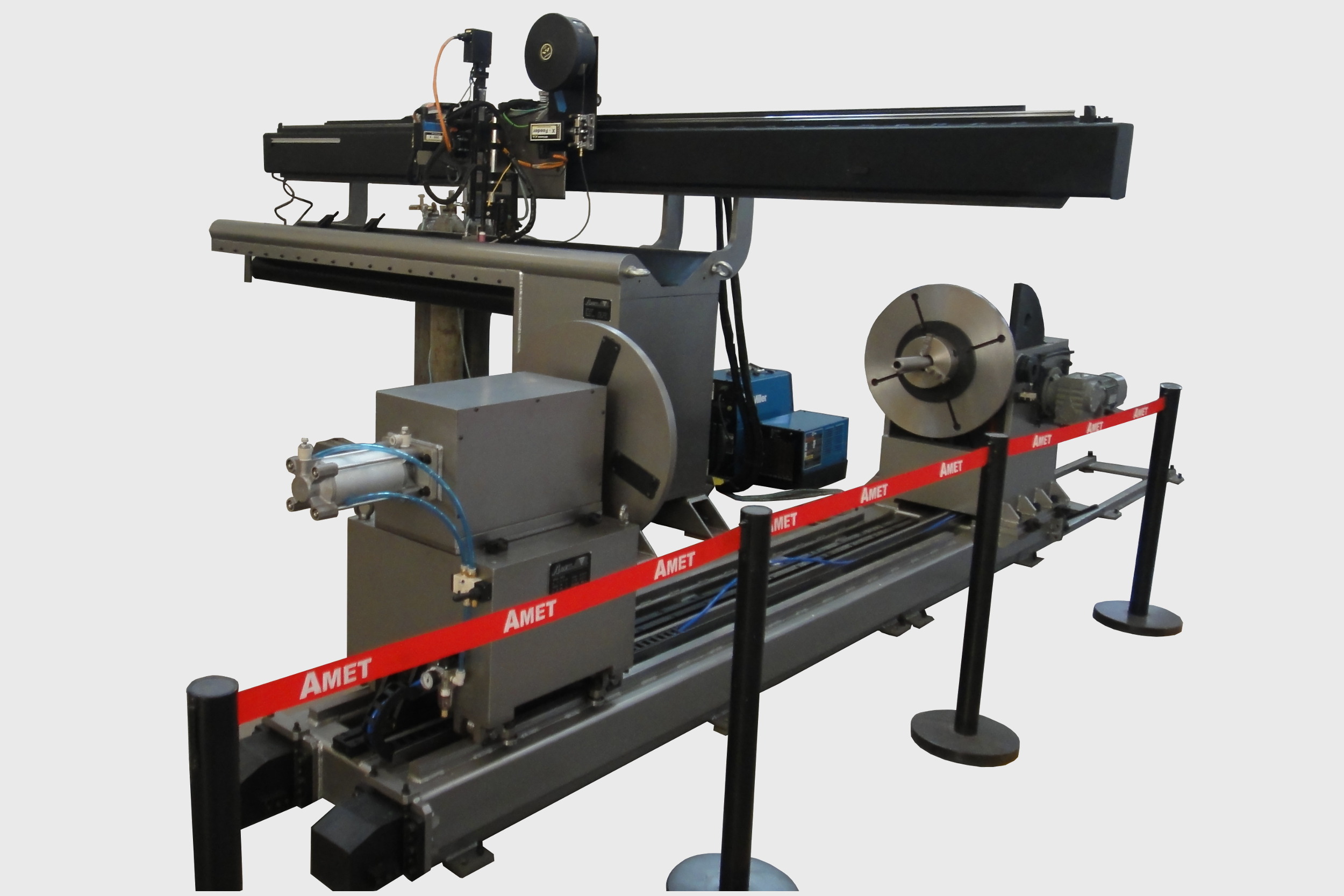

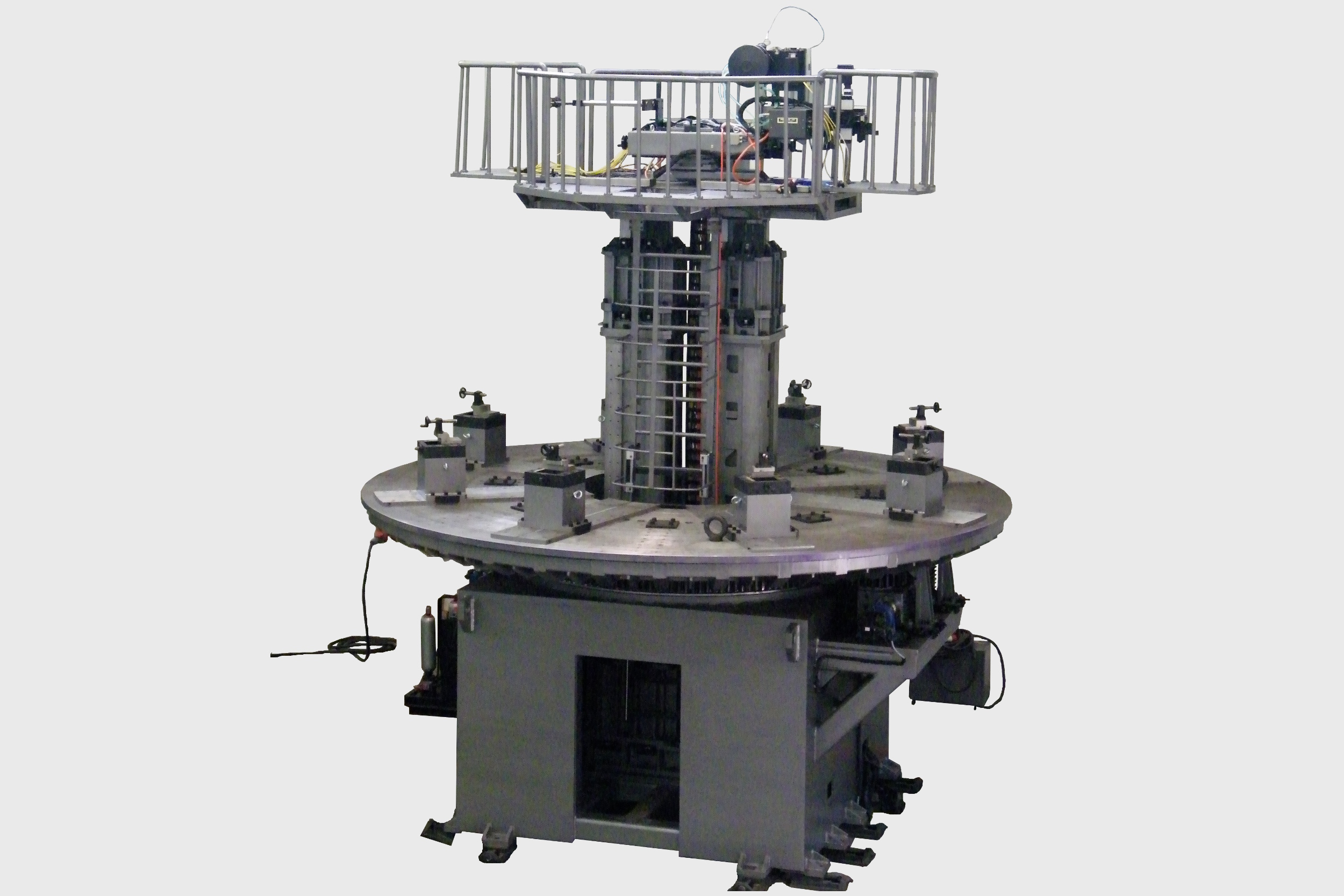

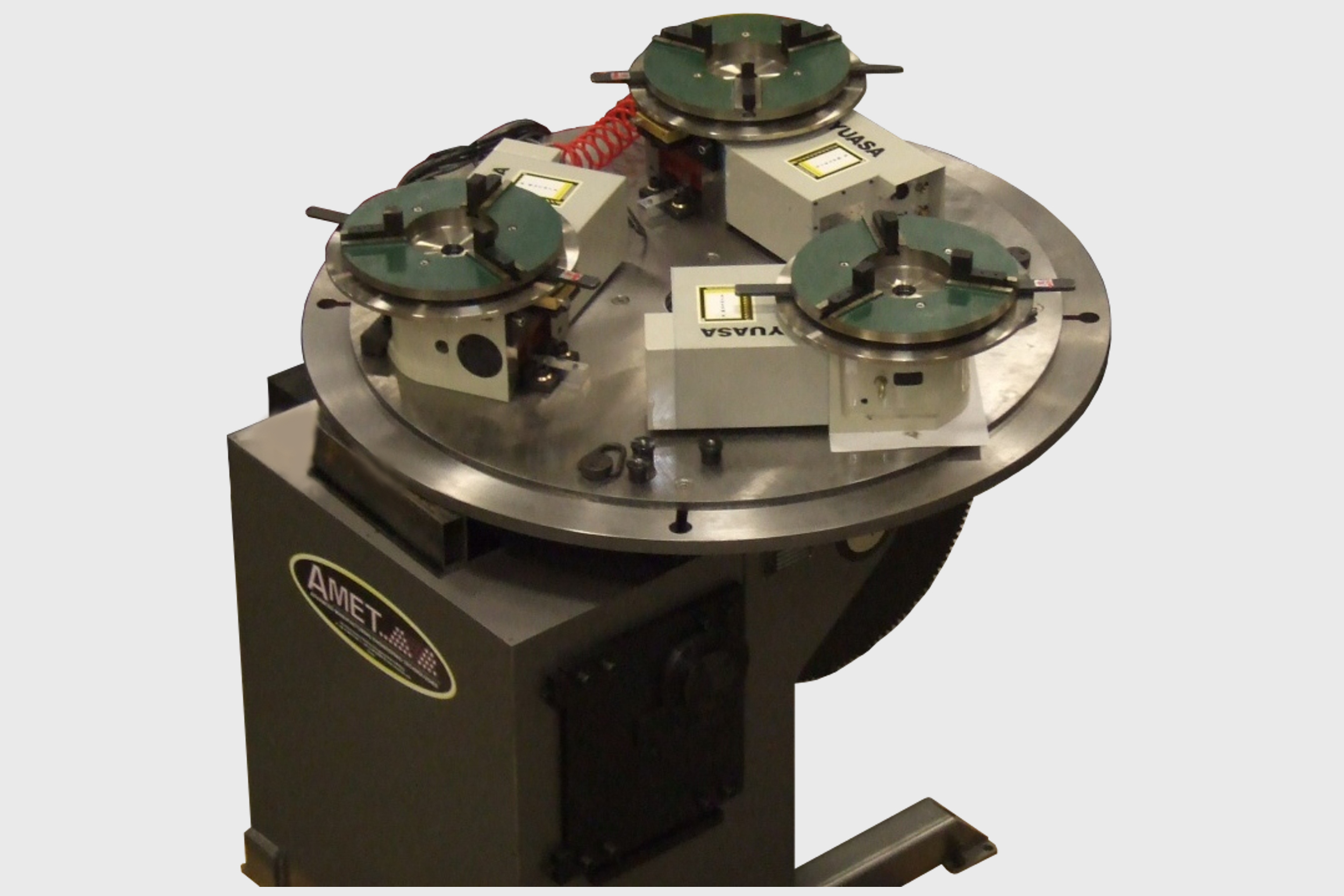

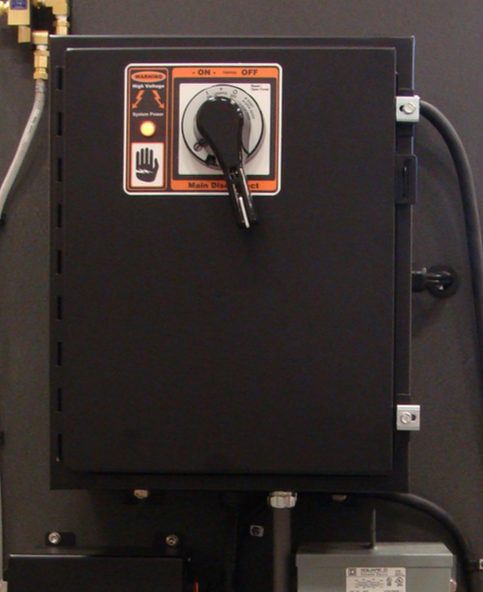

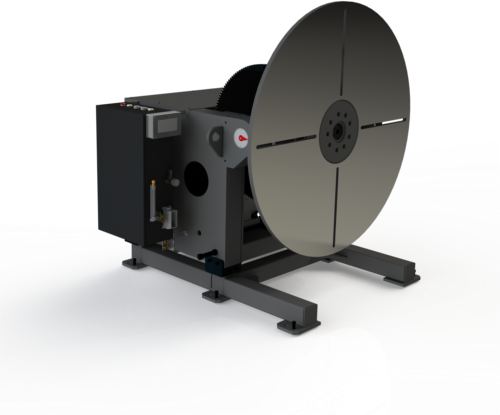

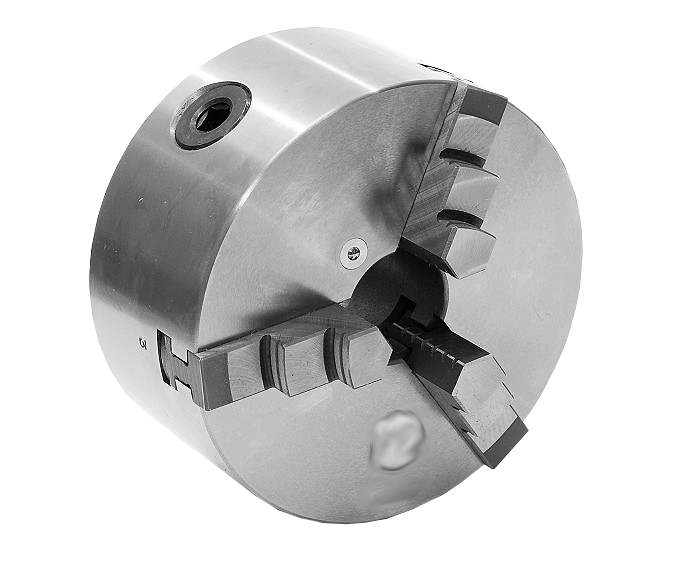

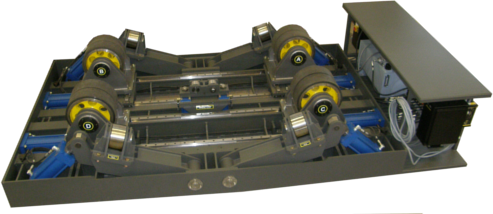

The architecture used in AMET's controls allow us to accommodate a wide range of power supplies, fixturing, safety, and automation. Many tasks can be automated, alleviating operator fatigue and increasing productivity.

3

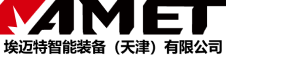

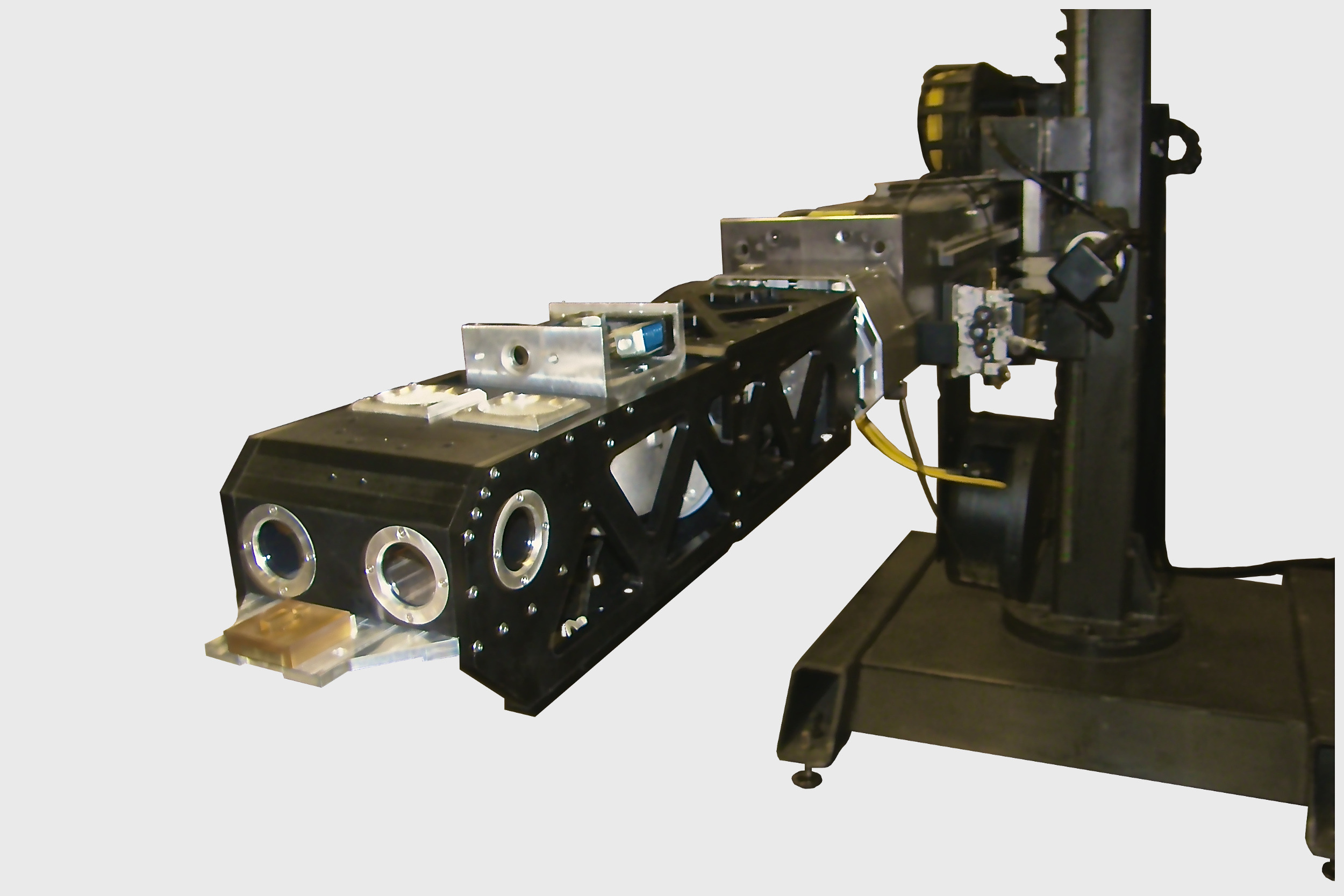

A combination of motorized and manually adjusted axes can be implemented to facilitate the most efficient use of the automation capacities in AMET's controls.

4

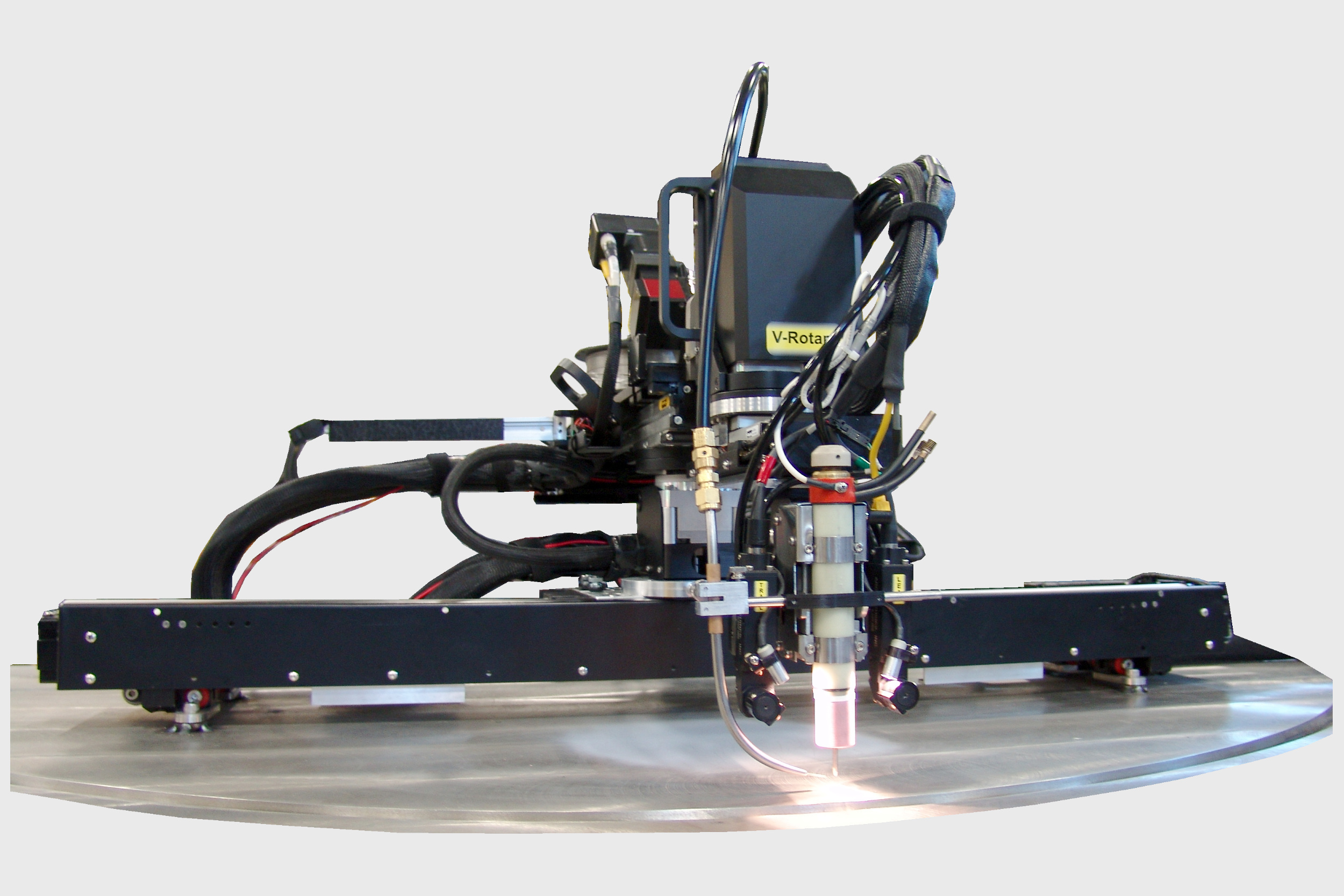

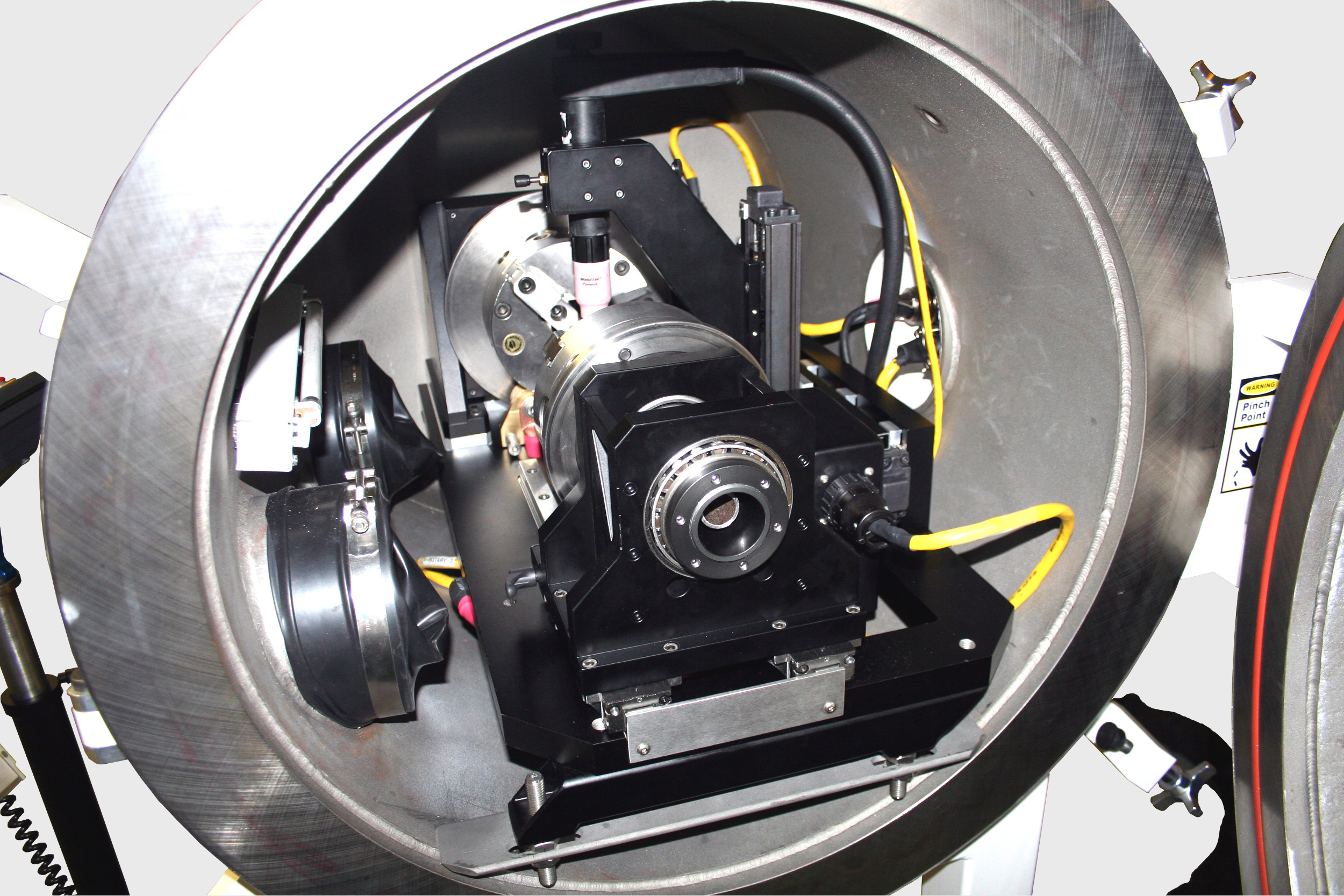

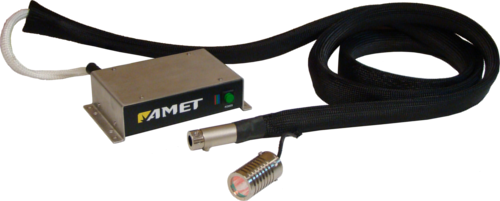

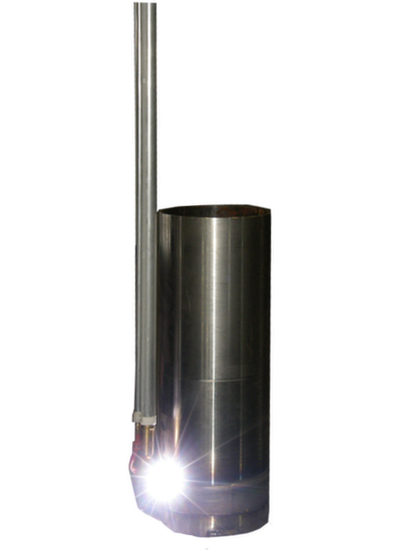

Adding camera systems to observe and record welds can be helpful when welding in remote or hard to view locations or when safety is in question.

5

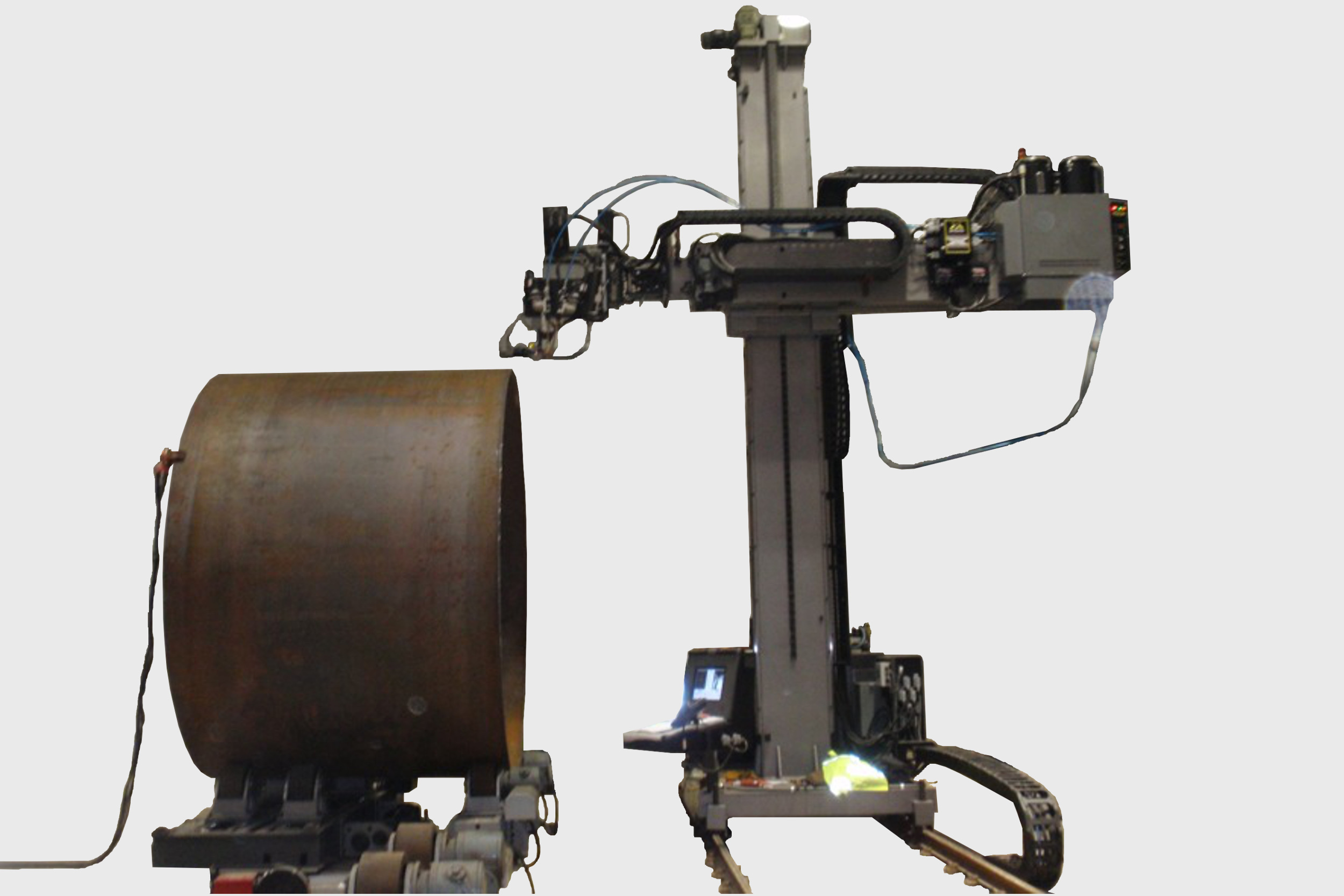

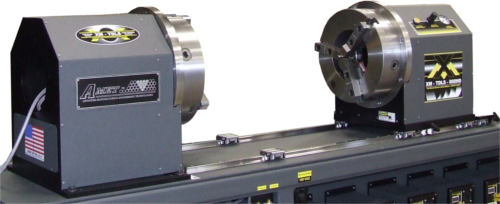

AMET can integrate our controls in nearly any type of fixture, from small bench top lathes, to seamers, to gigantic column and booms. If your application isn't on our website, give us a call.

6

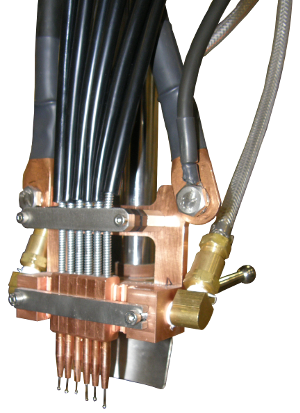

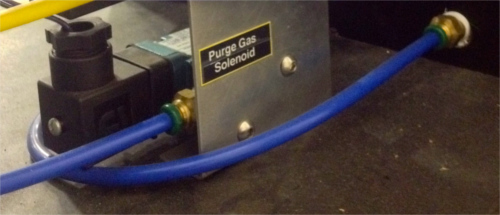

High quality cable is used throughout each system and is cut to length in order to keep a clean look and make an efficient use of space.

7

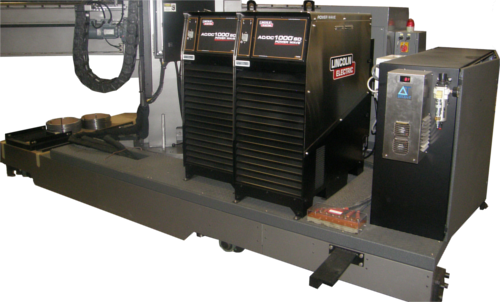

Our advanced controls can interface with many welding power supplies. If you have a certain PS in mind for your application, ask if our controls can communicate with it. Or we can choose a supply that will work best for your budget and application.

8

Each of our welding systems is installed by our staff of experienced technicians to ensure proper setup of the custom weld system.