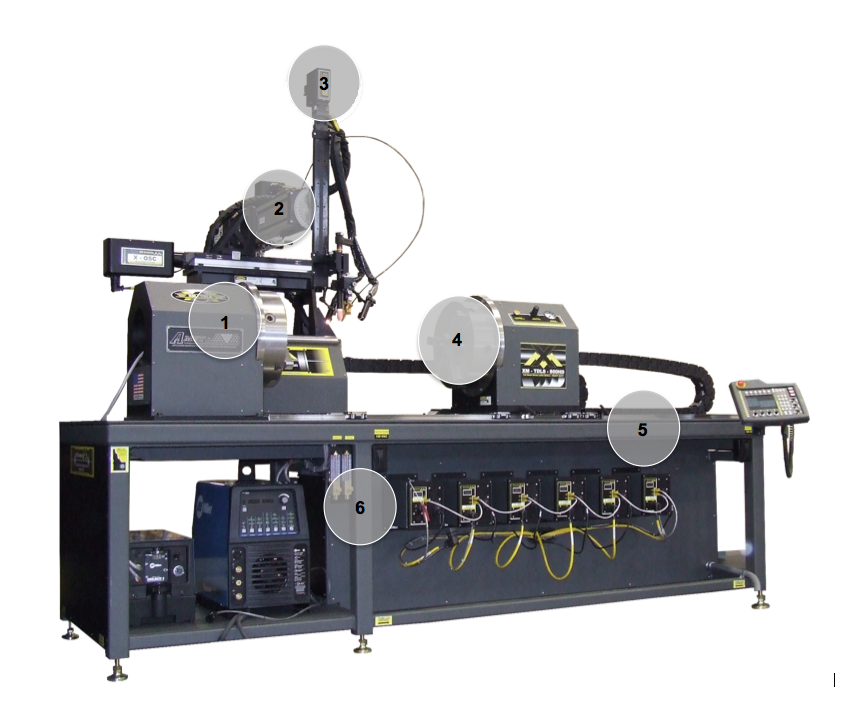

Standard Features on Heavy-Duty Bench Lathe Systems

1

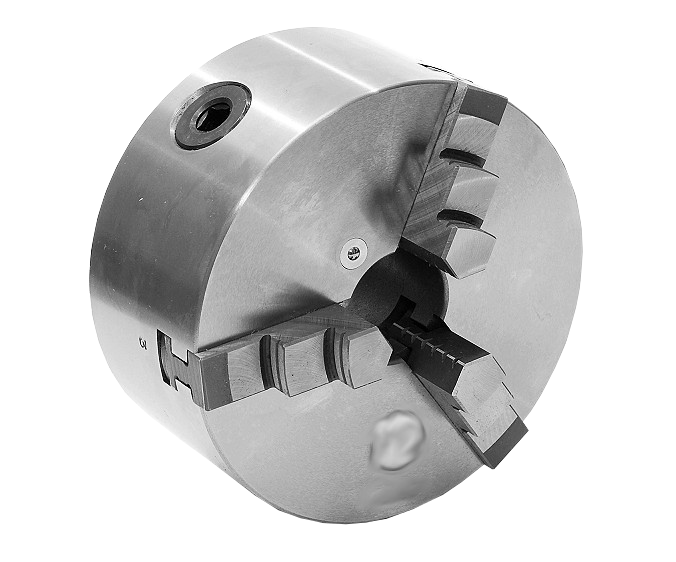

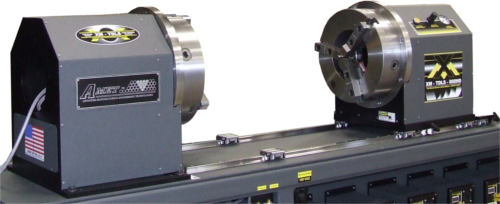

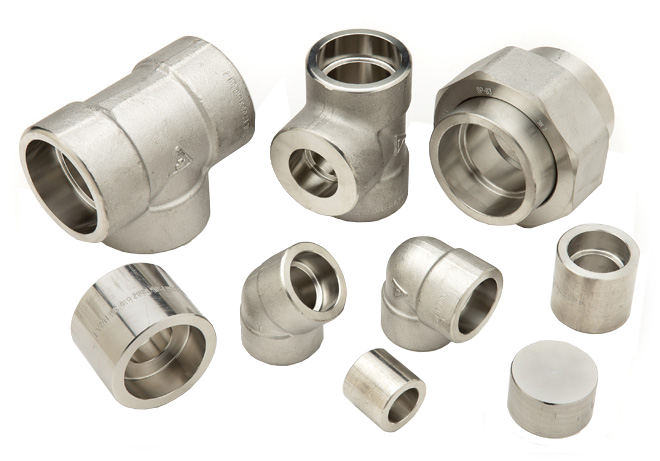

The precision headstock provides programmable and controllable rotation for part welding. The headstock features a manual 3-jaw chuck for holding the OD of parts up to 6 in (152 mm). The speed is controllable from 0 to 20 RPM.

2

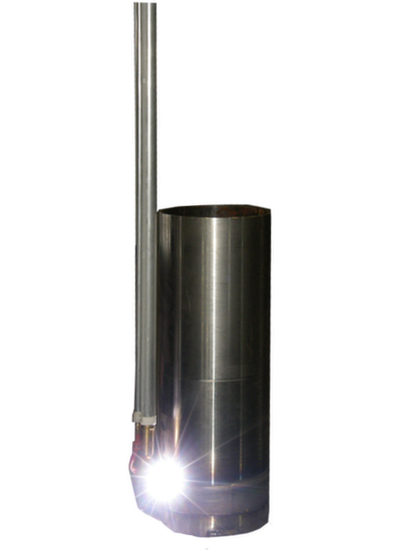

A pneumatic slide is included for horizontal motion of the torch. When activated, the slide quickly moves the torch towards and away from the centerline of the lathe. This motion can be programmed into the weld schedule to facilitate part loading and unloading, or controlled manually.

3

The vertical torch motion is provided by a precision motorized slide. The vertical motion is programmable for torch retraction after the weld to aid in part loading and unloading, and height adjustments for multi-pass welds.

4

The tailstock features pneumatic clamping to help hold the two pieces of the part in place during welding. The clamping is performed by a pneumatic cylinder that extends the tailstock horizontally towards the headstock to apply pressure to the two halves of the part being welded. The tailstock includes a faceplate with four tooling slots to provide mounting for tooling such as manual chucks or specialized fixtures.

5

Precision rails are included for both the tailstock and torch tower motion to ensure smooth and accurate positioning along the length of the lathe. These axes also include cable carriers to protect and organize the hoses and cables of the system.

6

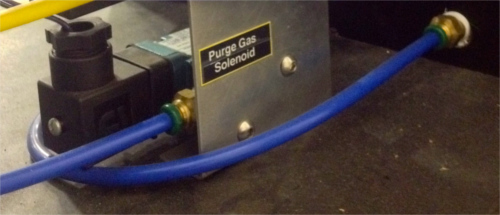

The lathe includes a workstation that provides a mounting location for the lathe assembly as well as the weld equipment. The welding power supply and other equipment are mounted beneath the workstation tabletop to provide a complete system that can easily be moved with a forklift. Only 1 pneumatic hose, 1 gas line, and 1 power circuit are required for this system to operate.