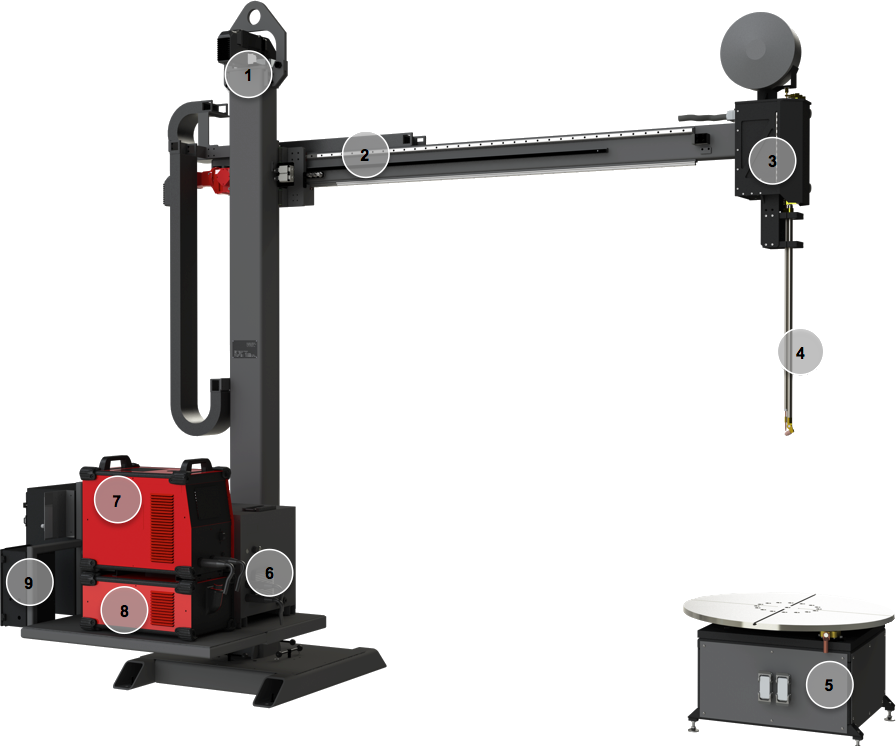

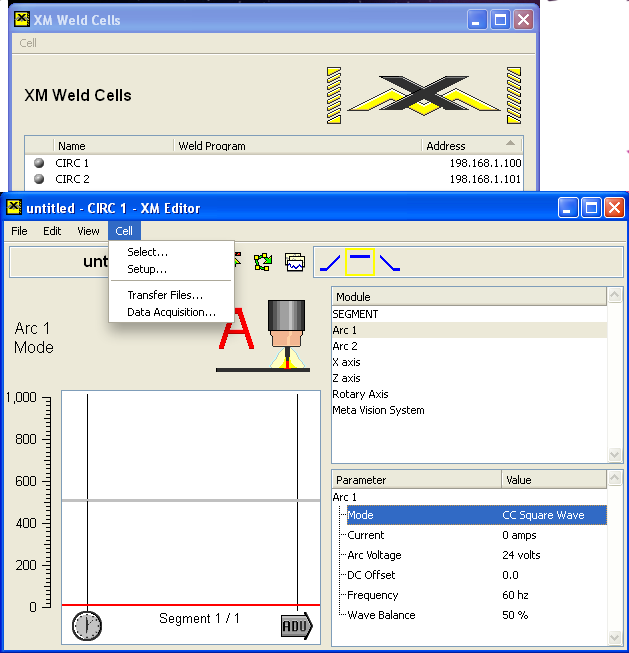

Standard Features on Integrated Precision Bore Cladder

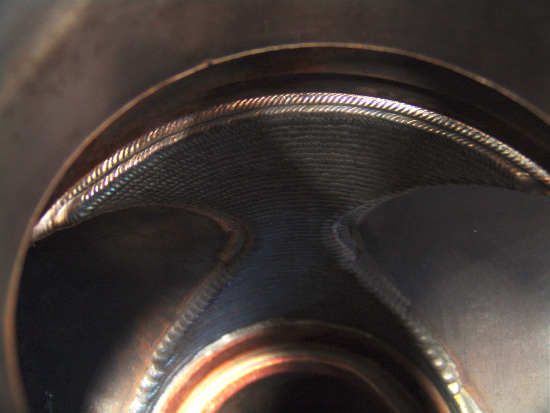

1

The precision column lift is achieved through a servo motor driven lead screw drive along machined rails. Precision lifting of the boom provides the system with the necessary vertical motion for spiral or step index cladding. A flexible cable carrier is included to organize and protect the life of the cables during motion.

2

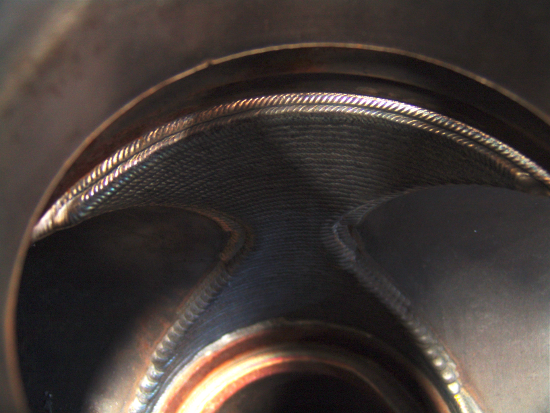

The precision boom drive features a servo motor driven rack and pinion drive along machined rails for horizontal motion of the bore torch. The precision drive is controlled and driven by an AVC (Arc Voltage Control) module for constant arc standoff during cladding. A flexible cable carrier is included to organize and protect the life of the cables during motion.

3

A 4-roll wire drive assembly that is driven by a servo motor with encoder feedback provides precision wire delivery. Wire feed speed, start delay, and wire retract are each programmable with the XM Controller. The wire feeder offers high-precision wire delivery with an accuracy of +/- 1% of the programmed speed. The wire feeder also includes a manual hotwire nozzle positioner that is mounted to the torch.

4

The AMET bore torch is water-cooled and equipped with the necessary components for hotwire feeding. The torch is rated at 200 Amps at 100 percent duty-cycle.

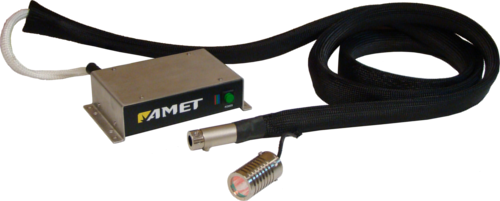

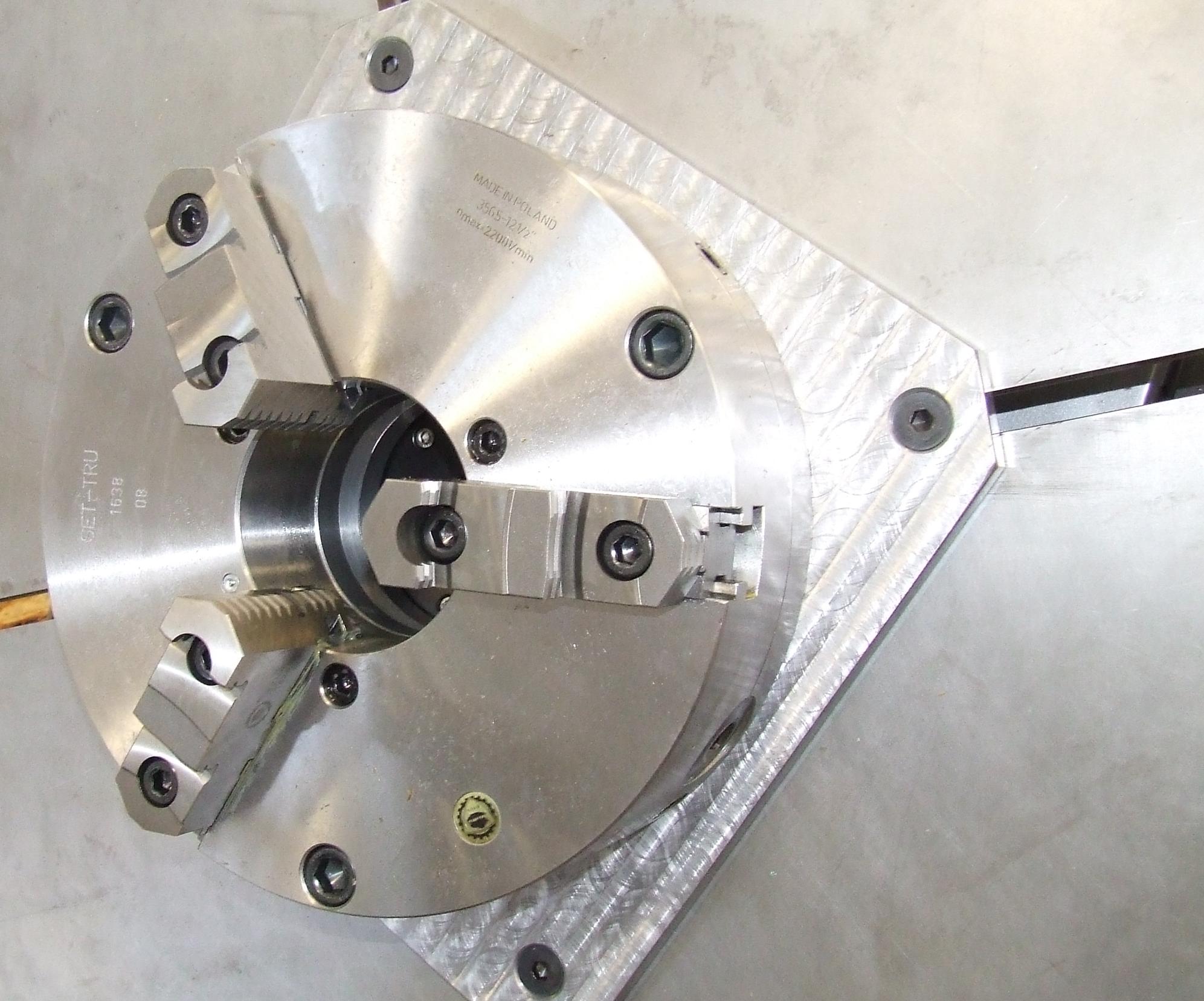

5

The included turn table is capable of continuous rotation for cladding the entire part without stopping. The rotating motion is controllable and programmable through the XM Controller.

6

AMET’s precision hotwire power supply preheats the wire prior to entering the weld puddle, which increases wire deposition over a cold wire GTAW system. The preheating of the welding wire also provides a cleaning effect, which improves the quality of the weld puddle. The current and voltage are adjustable up to 200 Amps and 20 Volts respectively.

7

A 350 Amp DC GTAW welding power supply is integrated into the system for programmable control of the weld parameters. The power supply is capable of cladding with a wide range of filler metals including hard metals like Inconel.

8

A 500 Amp water circulator is integrated into the system to prevent the weld torch from overheating.

9

A single point power distribution cabinet is included that provides fuse-protected power to the entire system from a single primary power circuit (provided by client).