Standard Features on 电弧监视系统

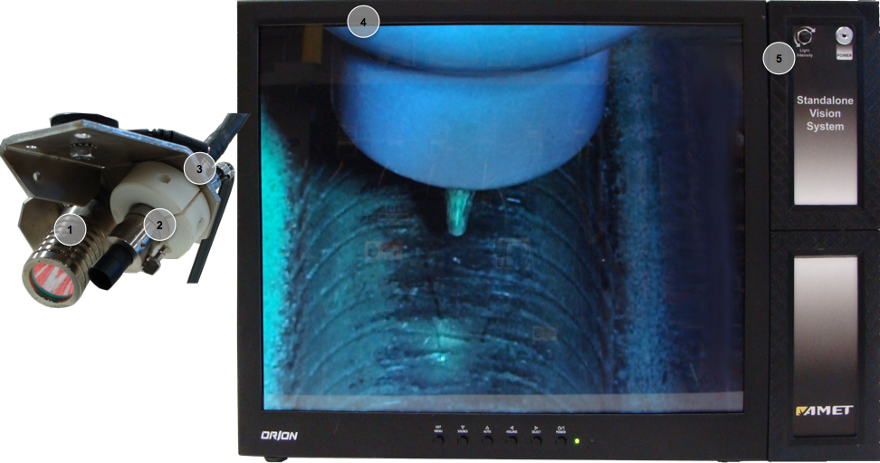

1

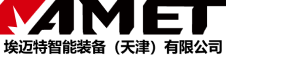

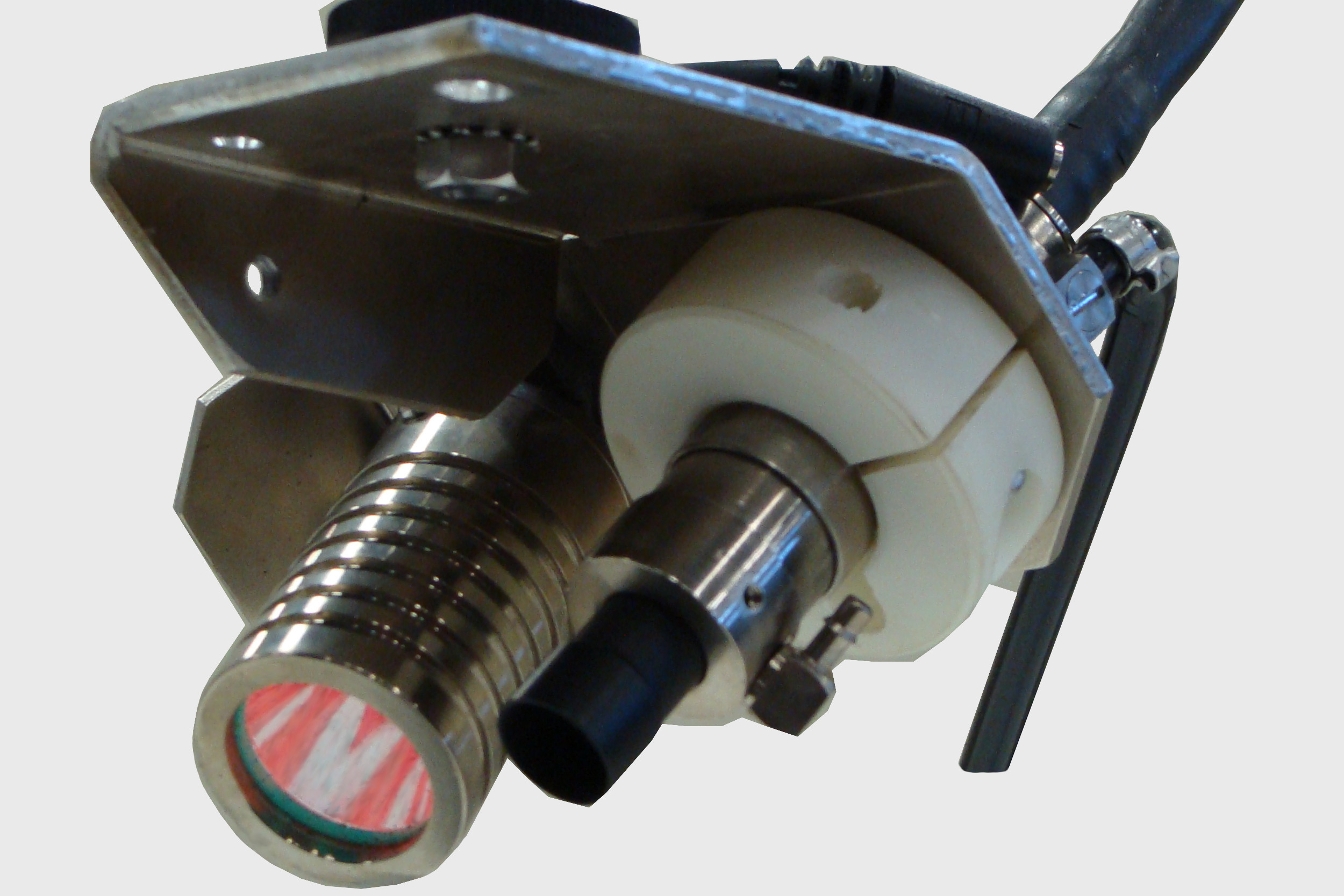

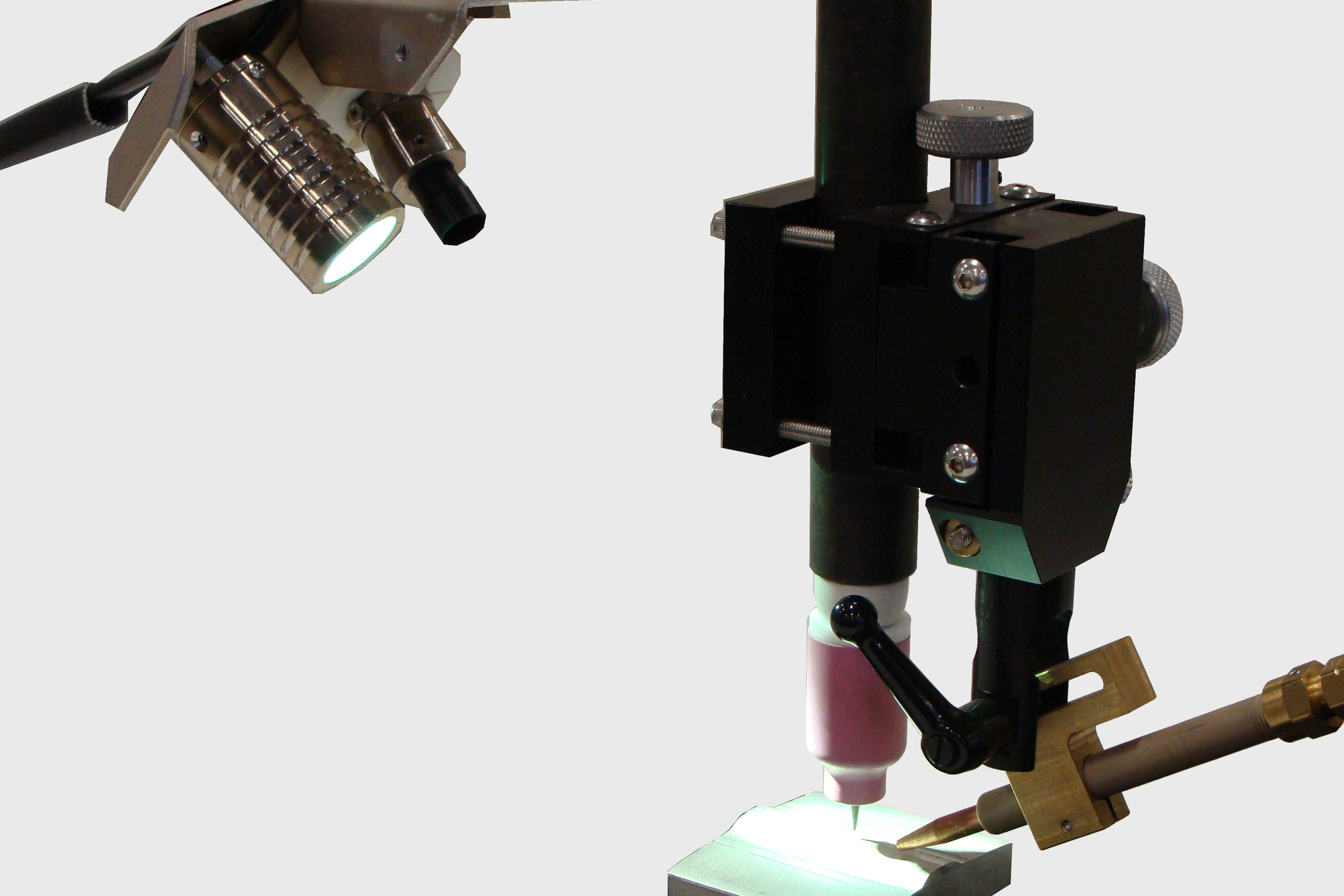

The integrated illuminator provides the necessary lighting for arc-off conditions. The light consists of bright LEDs or a halogen bulb to ensure the optimal image display in low-light conditions. The light aids in positioning the weld head during setup.

2

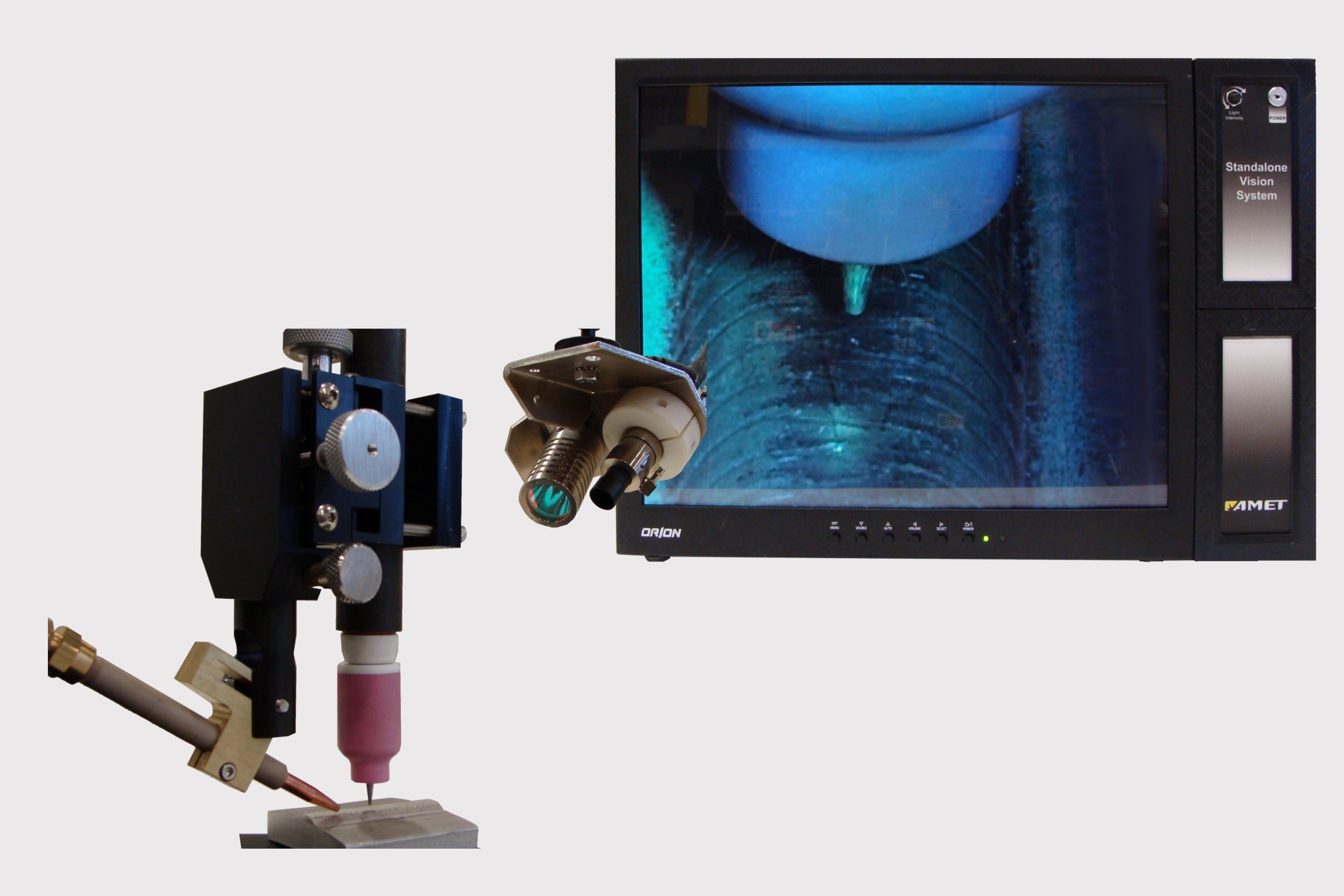

The camera body features a replaceable lens shield with manual focus adjustment and a set screw to prevent unwanted movement. Brackets for mounting the light source and camera body to the welding torch are included. The brackets are compatible with most TIG and Plasma machine torches.

3

A switch is located on the back of the camera body to activate a spot filter, which aids in proper camera positioning and filters excess light during welding. Alignment of the spot filter is done by moving the camera body so the top of the filter covers the bottom portion of the electrode. When the arc is ignited, the spot is automatically activated by the photo-sensor. The attenuation level of the spot filter is adjustable through a potentiometer.

4

A video module performs all of the necessary functions to automatically filter light, adjust shutter speed, adjust gain, and adjust color balance.

5

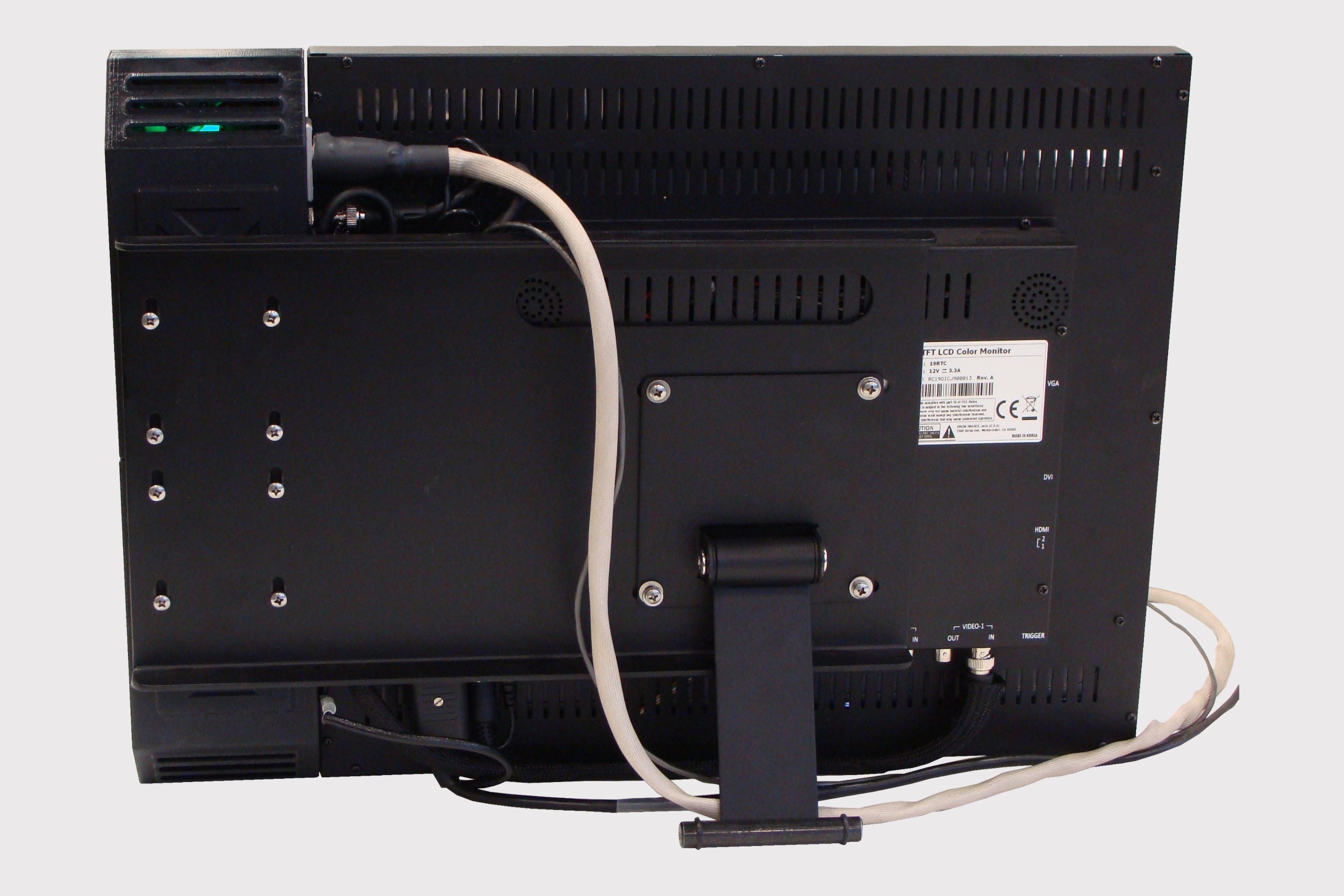

The monitor provides a high-resolution display of the video feed from the camera. The monitor also houses a potentiometer to adjust the light intensity from the light source.