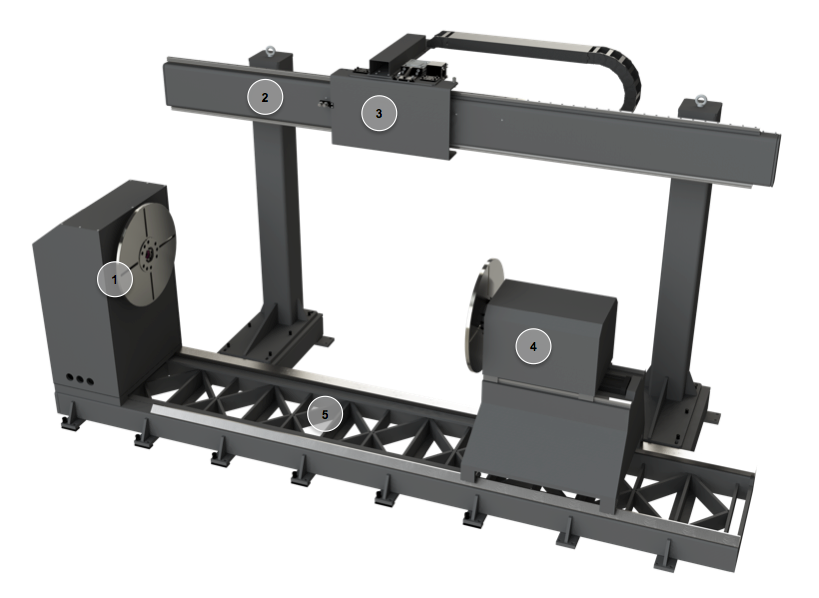

Standard Features on Industrial Weld Lathe Systems

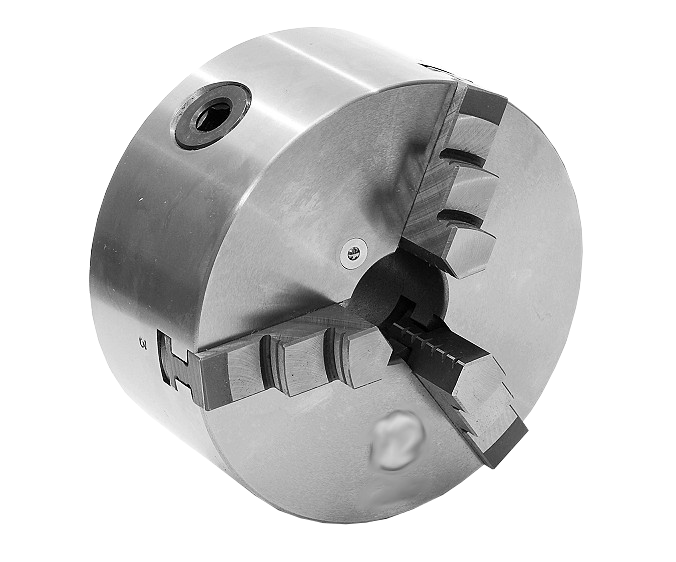

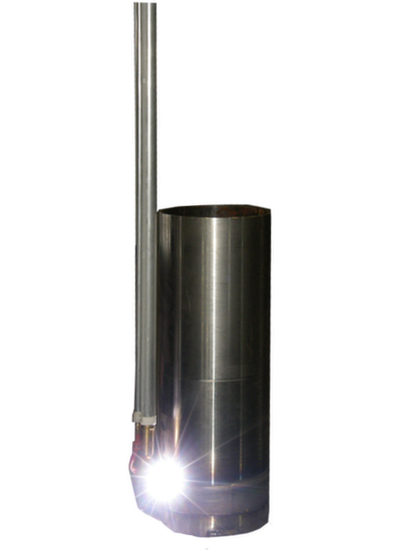

1

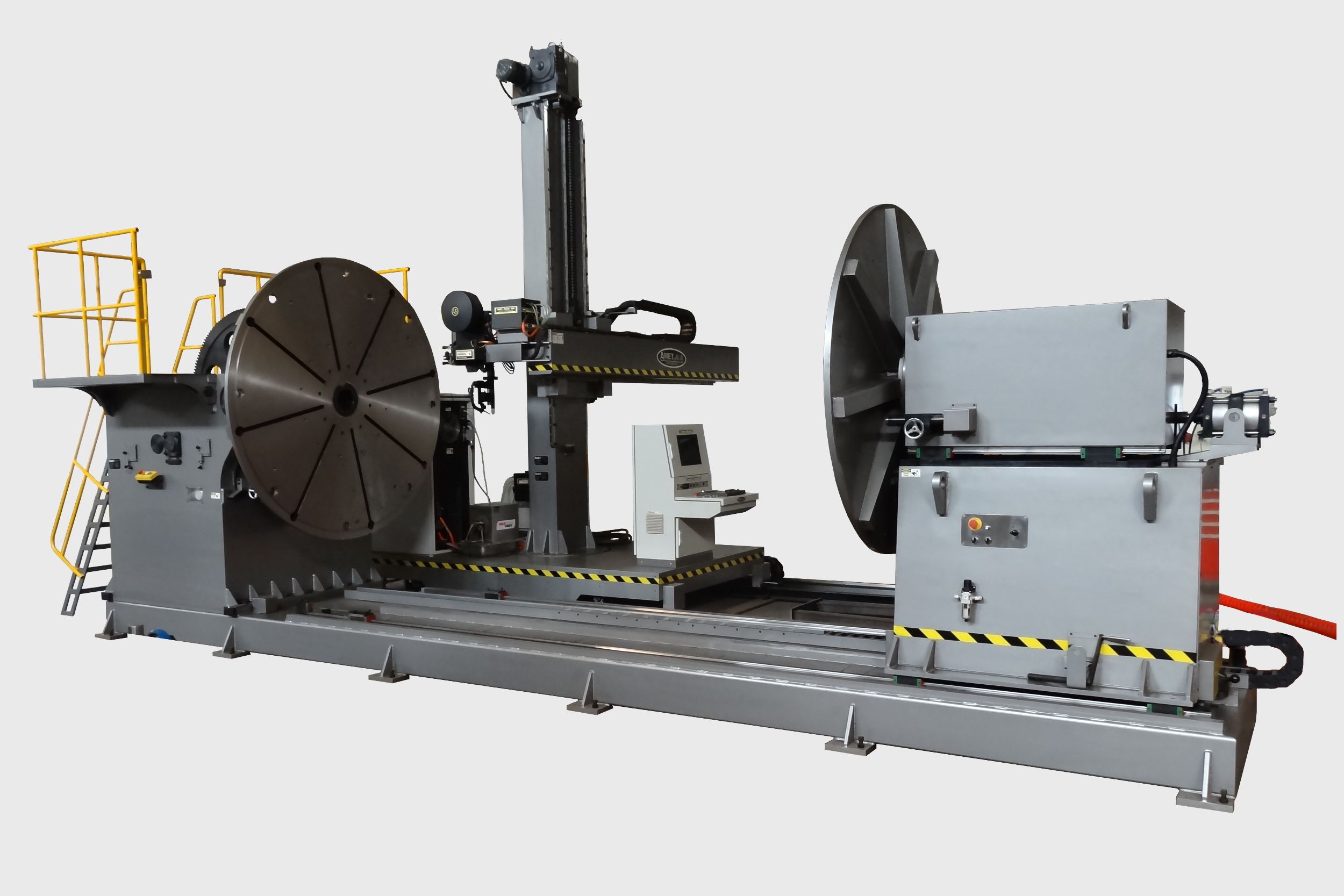

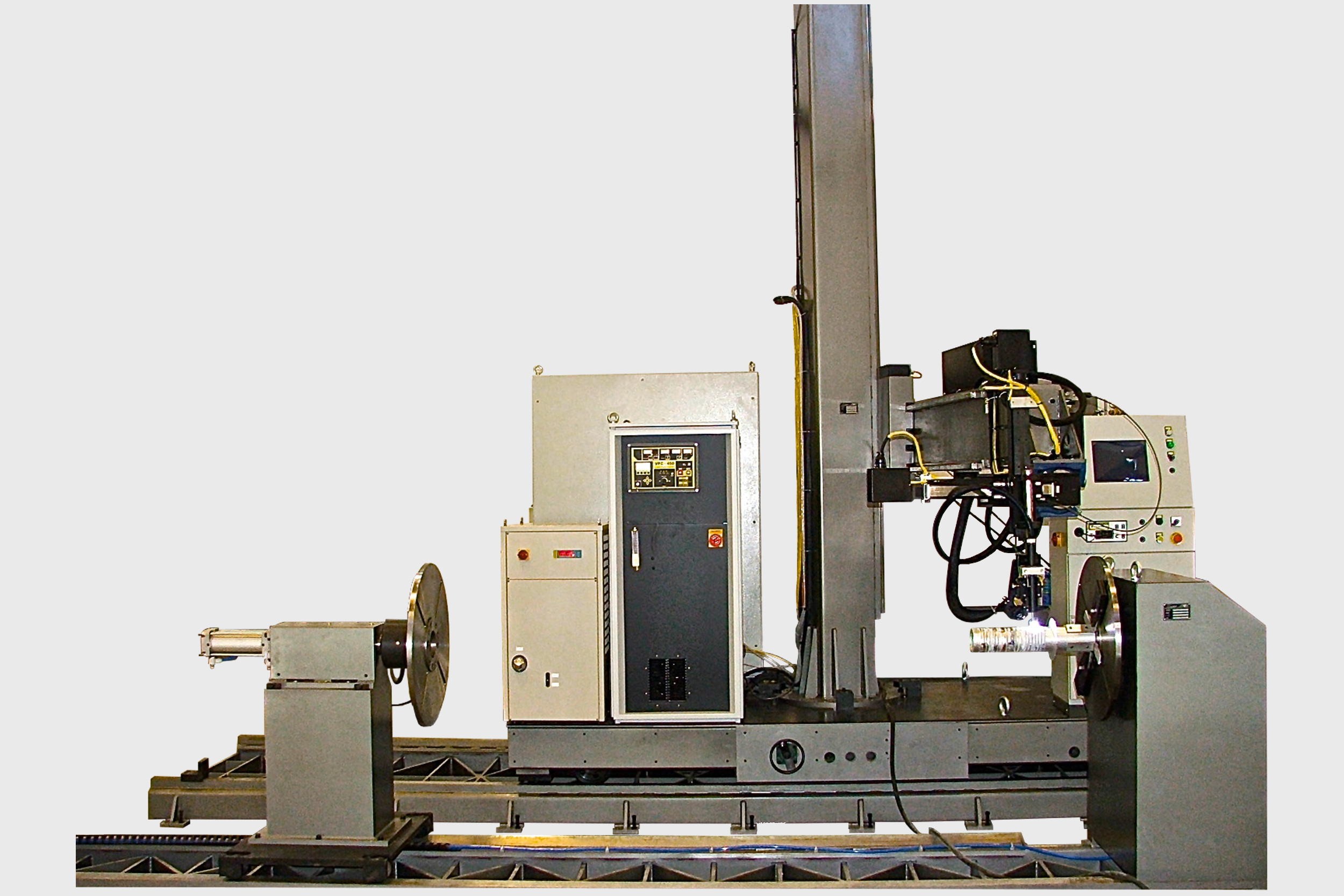

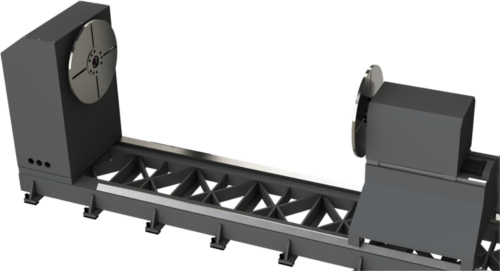

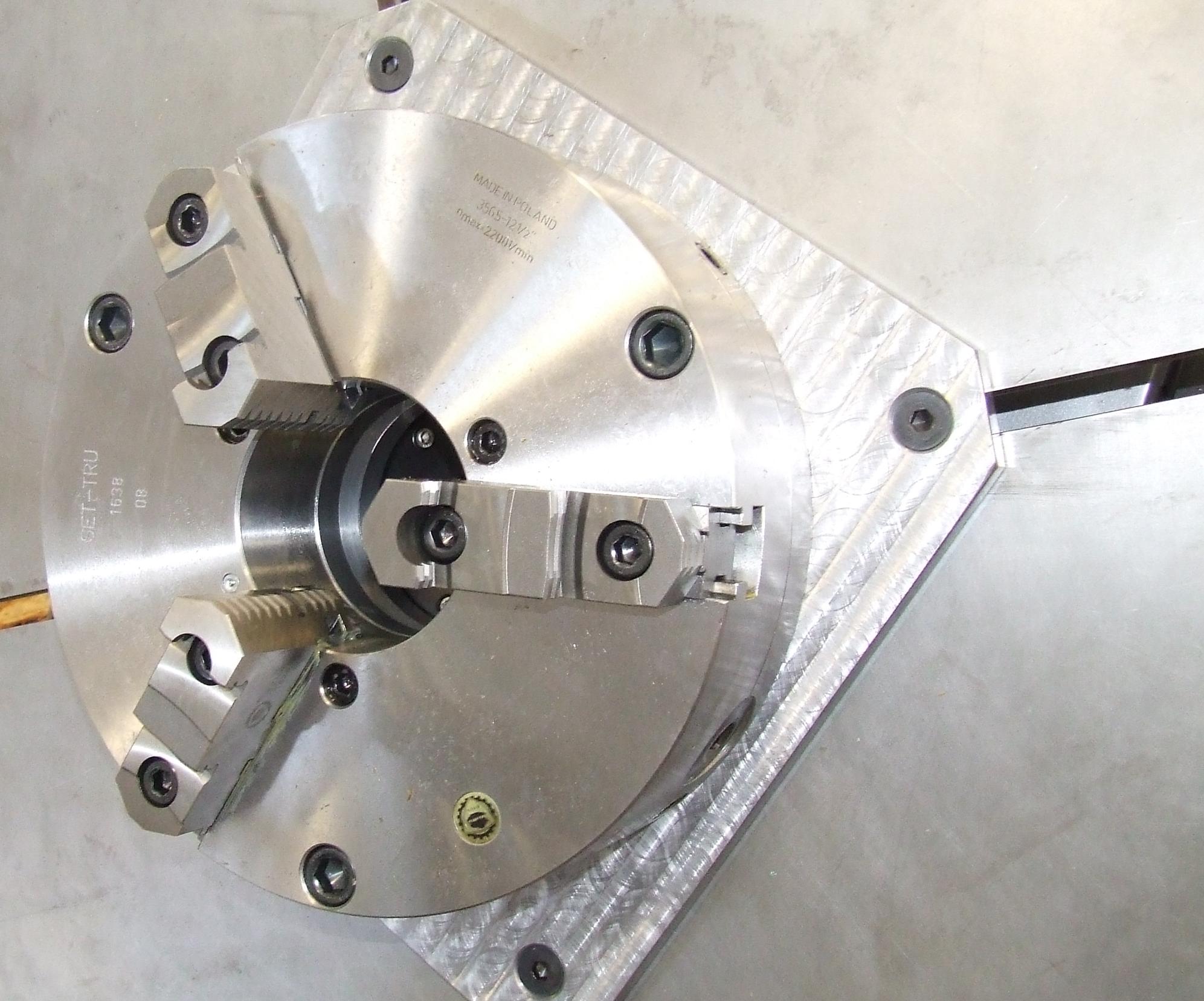

The headstock assembly provides programmable rotation for circumferential welding. The assembly is fixed into position and does not include linear motion along the length of the base. A faceplate with four (4) tooling slots and a thru hole is included for adding fixtures or additional gas capabilities.

2

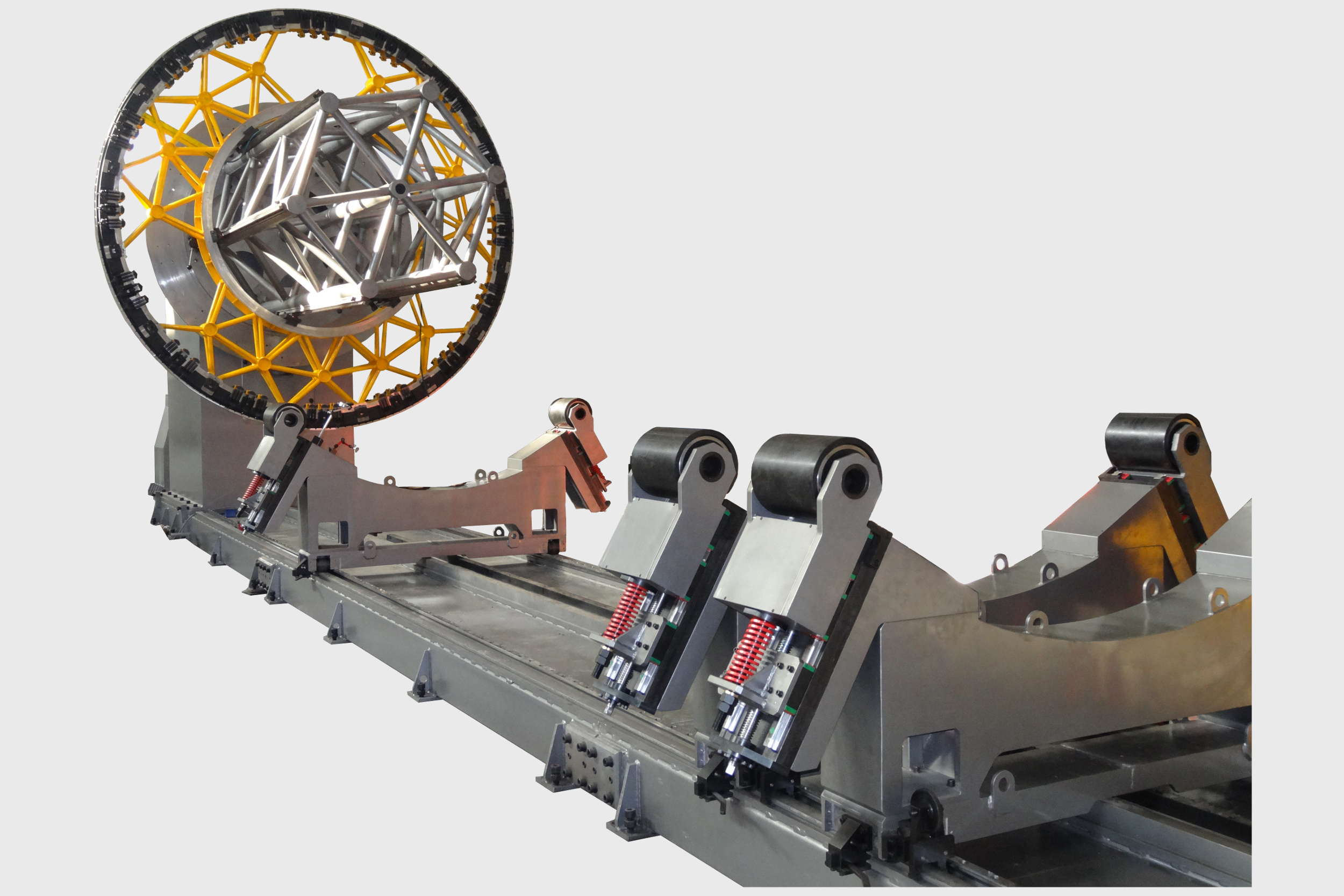

A track and supports are included for mounting the travel carriage. The track is made of thick steel to provide rigid support and a long service life with the capacity to support up to two (2) carriages. Rails are secured to the track for carriage motion.

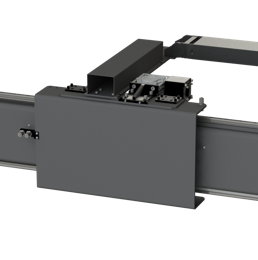

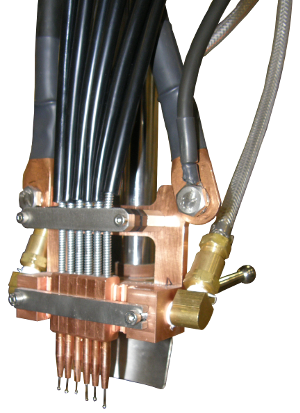

3

A non-motorized carriage is included for positioning the weld head. The carriage rides along the length of the track and includes manual brakes for locking it into position. A cable carrier is included to protect and organize the hoses and cables of the weld head.

4

The tailstock assembly features idler rotation and includes a faceplate with four (4) tooling slots and a thru hole. The assembly is capable of manual motion along the length of the lathe base and includes manual locks to prevent movement during operation. Pneumatic clamping is included to help hold parts securely in place.

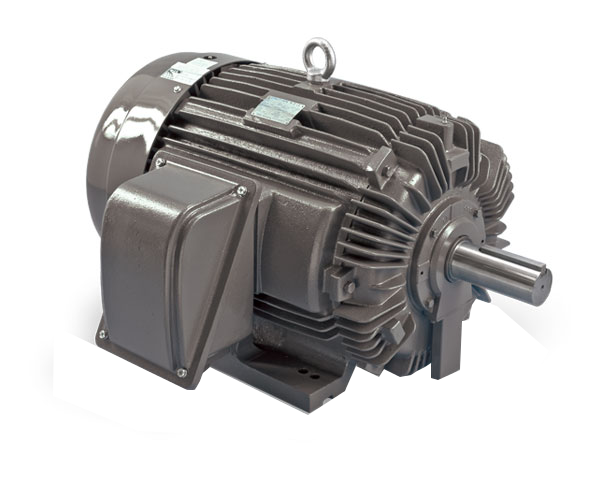

5

A sturdy base is included for supporting the entire lathe. The base allows for adjustment to ensure the lathe is level.